Page 307 - Pipeline Pigging Technology

P. 307

Pipeline Piggina Technology

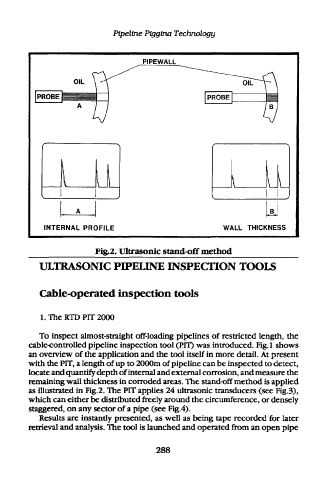

Fig.2. Ultrasonic stand-off method

ULTRASONIC PIPELINE INSPECTION TOOLS

Cable-operated inspection tools

1. The RTD PIT 2000

To inspect almost-straight off-loading pipelines of restricted length, the

cable-controlled pipeline inspection tool (PIT) was introduced. Fig.l shows

an overview of the application and the tool itself in more detail. At present

with the PIT, a length of up to 2000m of pipeline can be inspected to detect,

locate and quantify depth of internal and external corrosion, and measure the

remaining wall thickness in corroded areas. The stand-off method is applied

as illustrated in Fig.2. The PIT applies 24 ultrasonic transducers (see Fig.3),

which can either be distributed freely around the circumference, or densely

staggered, on any sector of a pipe (see Fig.4).

Results are instantly presented, as well as being tape recorded for later

retrieval and analysis. The tool is launched and operated from an open pipe

288