Page 308 - Pipeline Pigging Technology

P. 308

Cable-operated and self-contained ultrasonic pigs

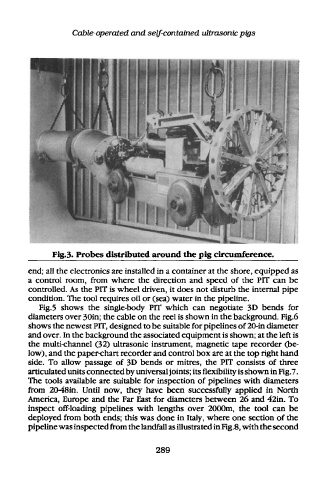

Fig.3. Probes distributed around the pig circumference.

end; all the electronics are installed in a container at the shore, equipped as

a control room, from where the direction and speed of the PIT can be

controlled. As the PIT is wheel driven, it does not disturb the internal pipe

condition. The tool requires oil or (sea) water in the pipeline.

Fig.5 shows the single-body PIT which can negotiate 3D bends for

diameters over 30in; the cable on the reel is shown in the background. Fig.6

shows the newest PIT, designed to be suitable for pipelines of 20-in diameter

and over. In the background the associated equipment is shown; at the left is

the multi-channel (32) ultrasonic instrument, magnetic tape recorder (be-

low), and the paper-chart recorder and control box are at the top right hand

side. To allow passage of 3D bends or mitres, the PIT consists of three

articulated units connected by universal joints; its flexibility is shown in Fig.7.

The tools available are suitable for inspection of pipelines with diameters

from 20-48in. Until now, they have been successfully applied in North

America, Europe and the Far East for diameters between 26 and 42in. To

inspect off-loading pipelines with lengths over 2000m, the tool can be

deployed from both ends; this was done in Italy, where one section of the

pipeline was inspected from the landfall as illustrated in Fig.8, with the second

289