Page 314 - Pipeline Pigging Technology

P. 314

Cable-operated and self-contained ultrasonic pigs

3. Stripper PIT testing

For relatively-large pipe diameters (at present I6in), wheel-driven inspec-

tion tools such as the various PlTs described are attractive; this technology

cannot be used for small diameters.

To propel such tools with cables over long distances, up to 6000m, as well

as through bends, high pulling forces are required which cannot be generated

by small crawlers. Therefore, the stripper technique has been developed, as

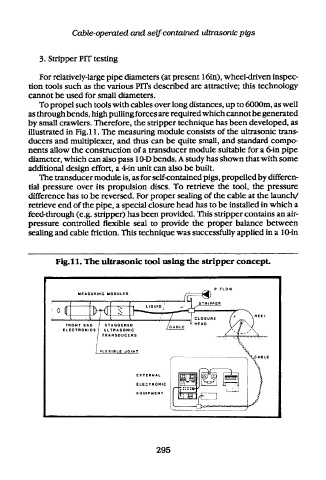

illustrated in Fig.l 1. The measuring module consists of the ultrasonic trans-

ducers and multiplexer, and thus can be quite small, and standard compo-

nents allow the construction of a transducer module suitable for a 6-in pipe

diameter, which can also pass 10-D bends. A study has shown that with some

additional design effort, a 4-in unit can also be built.

The transducer module is, as for self-contained pigs, propelled by differen-

tial pressure over its propulsion discs. To retrieve the tool, the pressure

difference has to be reversed. For proper sealing of the cable at the launch/

retrieve end of the pipe, a special closure head has to be installed in which a

feed-through (e.g. stripper) has been provided. This stripper contains an air-

pressure controlled flexible seal to provide the proper balance between

sealing and cable friction. This technique was successfully applied in a 10-in

Fig. 11. The ultrasonic tool using the stripper concept.

295