Page 317 - Pipeline Pigging Technology

P. 317

Pipeline Pigging Technology

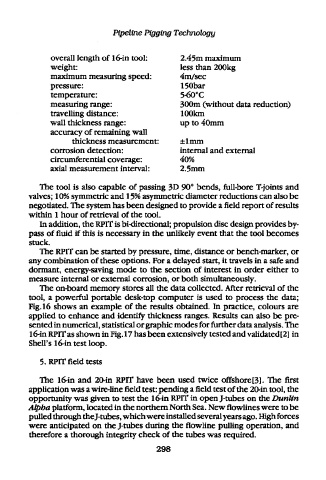

overall length of 16-in tool: 2.45m maximum

weight: less than 200kg

maximum measuring speed: 4m/sec

pressure: 150bar

temperature: 5-60°C

measuring range: 300m (without data reduction)

travelling distance: 100km

wall thickness range: up to 40mm

accuracy of remaining wall

thickness measurement: ± 1 mm

corrosion detection: internal and external

circumferential coverage: 40%

axial measurement interval: 2.5mm

The tool is also capable of passing 3D 90° bends, full-bore T-joints and

valves; 10% symmetric and 15% asymmetric diameter reductions can also be

negotiated. TTie system has been designed to provide a field report of results

within 1 hour of retrieval of the tool.

In addition, the RPIT is bi-directional; propulsion disc design provides by-

pass of fluid if this is necessary in the unlikely event that the tool becomes

stuck.

The RPIT can be started by pressure, time, distance or bench-marker, or

any combination of these options. For a delayed start, it travels in a safe and

dormant, energy-saving mode to the section of interest in order either to

measure internal or external corrosion, or both simultaneously.

The on-board memory stores all the data collected. After retrieval of the

tool, a powerful portable desk-top computer is used to process the data;

Fig. 16 shows an example of the results obtained. In practice, colours are

applied to enhance and identify thickness ranges. Results can also be pre-

sented in numerical, statistical or graphic modes for further data analysis. The

16-in RPIT as shown in Fig. 17 has been extensively tested and validated[2] in

Shell's 16-in test loop.

5. RPIT field tests

The 16-in and 20-in RPIT have been used twice offshore[3]. The first

application was a wire-line field test: pending a field test of the 20-in tool, the

opportunity was given to test the 16-in RPIT in open J-tubes on the Dunlin

Alpha platform, located in the northern North Sea. New flowlines were to be

pulled through the J-tubes, which were installed several years ago. High forces

were anticipated on the J-tubes during the flowline pulling operation, and

therefore a thorough integrity check of the tubes was required.

298