Page 318 - Pipeline Pigging Technology

P. 318

Coble-operated and self-contained ultrasonic pigs

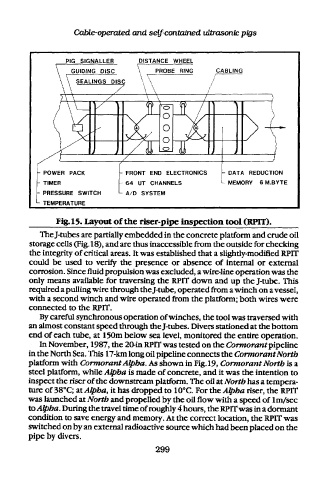

Fig. 15. Layout of the riser-pipe inspection tool (RPlT).

The J-tubes are partially embedded in the concrete platform and crude oil

storage cells (Fig. 18), and are thus inaccessible from the outside for checking

the integrity of critical areas. It was established that a slightly-modified RPIT

could be used to verify the presence or absence of internal or external

corrosion. Since fluid propulsion was excluded, a wire-line operation was the

only means available for traversing the RPIT down and up the J-tube. This

required a pulling wire through the J-tube, operated from a winch on a vessel,

with a second winch and wire operated from the platform; both wires were

connected to the RPIT.

By careful synchronous operation of winches, the tool was traversed with

an almost constant speed through the J-tubes. Divers stationed at the bottom

end of each tube, at 150m below sea level, monitored the entire operation.

In November, 1987, the 20-in RPIT was tested on the Cormorant pipeline

in the North Sea. This 17-km long oil pipeline connects the Cormorant North

platform with Cormorant Alpha. As shown in Fig. 19, Cormorant North is a

steel platform, while Alpha is made of concrete, and it was the intention to

inspect the riser of the downstream platform. The oil at North has a tempera-

ture of 38°C; at Alpha, it has dropped to 10°C. For the Alpha riser, the RPIT

was launched at North and propelled by the oil flow with a speed of Im/sec

to Alpha. During the travel time of roughly 4 hours, the RPIT was in a dormant

condition to save energy and memory. At the correct location, the RPIT was

switched on by an external radioactive source which had been placed on the

pipe by divers.

299