Page 331 - Pipeline Pigging Technology

P. 331

Pipeline Pigging Technology

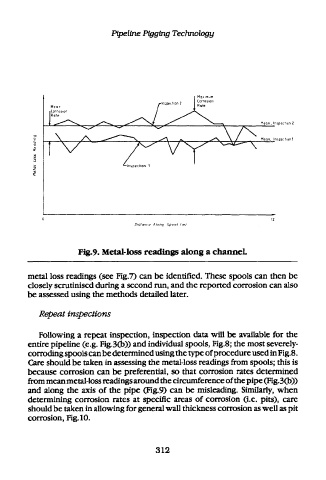

Fig.9. Metal-loss readings along a channel.

metal loss readings (see Fig.7) can be identified. These spools can then be

closely scrutinised during a second run, and the reported corrosion can also

be assessed using the methods detailed later.

Repeat inspections

Following a repeat inspection, inspection data will be available for the

entire pipeline (e.g. Fig.3(b)) and individual spools, Fig.8; the most severely-

corroding spools can be determined using the type of procedure used in Fig.8.

Care should be taken in assessing the metal-loss readings from spools; this is

because corrosion can be preferential, so that corrosion rates determined

from mean metal-loss readings around the circumference of the pipe (Fig.3(b))

and along the axis of the pipe (Fig.9) can be misleading. Similarly, when

determining corrosion rates at specific areas of corrosion (i.e. pits), care

should be taken in allowing for general wall thickness corrosion as well as pit

corrosion, Fig. 10.

312