Page 333 - Pipeline Pigging Technology

P. 333

Pipeline Pigging Technology

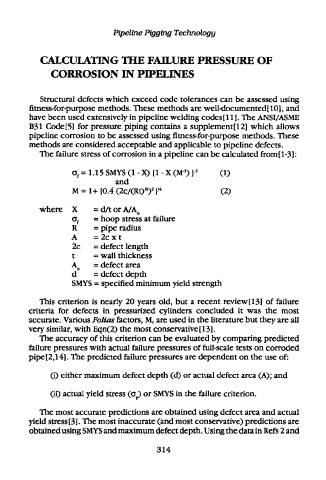

CALCULATING THE FAILURE PRESSURE OF

CORROSION IN PIPELINES

Structural defects which exceed code tolerances can be assessed using

fitness-for-purpose methods. These methods are well-documented[10], and

have been used extensively in pipeline welding codes[ll]. The ANSI/ASME

B31 Code [5] for pressure piping contains a supplement[12] which allows

pipeline corrosion to be assessed using fitness-for-purpose methods. These

methods are considered acceptable and applicable to pipeline defects.

The failure stress of corrosion in a pipeline can be calculated from [1-3]:

1

O f = 1.15 SMYS (1 - X) {1 - X (M' ) }•' (1)

and

V4 2

M = 1 + {0.4 (2c/(Rt) ) p (2)

where X = d/t or A/A o

= hoop stress at failure

o f

R = pipe radius

A = 2c x t

2c = defect length

t = wall thickness

= defect area

A o

d° = defect depth

SMYS = specified minimum yield strength

This criterion is nearly 20 years old, but a recent review[13] of failure

criteria for defects in pressurized cylinders concluded it was the most

accurate. Various Folios factors, M, are used in the literature but they are all

very similar, with Eqn(2) the most conservative [13].

The accuracy of this criterion can be evaluated by comparing predicted

failure pressures with actual failure pressures of full-scale tests on corroded

pipe [2,14]. The predicted failure pressures are dependent on the use of:

(i) either maximum defect depth (d) or actual defect area (A); and

(ii) actual yield stress (CT) or SMYS in the failure criterion.

The most accurate predictions are obtained using defect area and actual

yield stress [3]. The most inaccurate (and most conservative) predictions are

obtained using SMYS and maximum defect depth. Using the data in Refs 2 and

314