Page 363 - Pipeline Pigging Technology

P. 363

Pipeline Pigging Technology

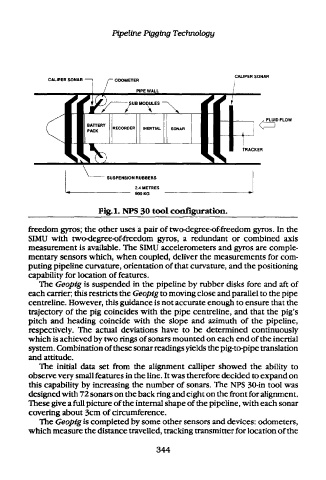

Fig.l. NFS 30 tool configuration.

freedom gyros; the other uses a pair of two-degree-of-freedom gyros. In the

SIMU with two-degree-of-freedom gyros, a redundant or combined axis

measurement is available. The SIMU accelerometers and gyros are comple-

mentary sensors which, when coupled, deliver the measurements for com-

puting pipeline curvature, orientation of that curvature, and the positioning

capability for location of features.

The Geoptg is suspended in the pipeline by rubber disks fore and aft of

each carrier; this restricts the Geoptg to moving close and parallel to the pipe

centreline. However, this guidance is not accurate enough to ensure that the

trajectory of the pig coincides with the pipe centreline, and that the pig's

pitch and heading coincide with the slope and azimuth of the pipeline,

respectively. The actual deviations have to be determined continuously

which is achieved by two rings of sonars mounted on each end of the inertial

system. Combination of these sonar readings yields the pig-to-pipe translation

and attitude.

The initial data set from the alignment calliper showed the ability to

observe very small features in the line. It was therefore decided to expand on

this capability by increasing the number of sonars. The NFS 30-in tool was

designed with 72 sonars on the back ring and eight on the front for alignment.

These give a full picture of the internal shape of the pipeline, with each sonar

covering about 3cm of circumference.

The Geopig is completed by some other sensors and devices: odometers,

which measure the distance travelled, tracking transmitter for location of the

344