Page 371 - Pipeline Pigging Technology

P. 371

Pipeline Pigging Technology

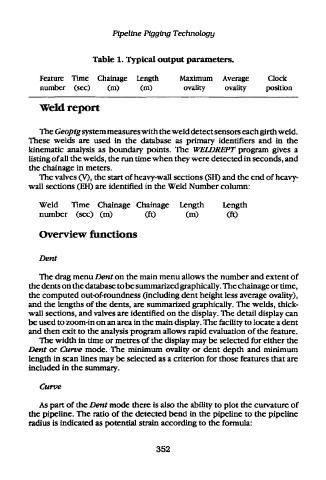

Table 1. Typical output parameters.

Feature Time Chainage Length Maximum Average Clock

number (sec) (m) (m) ovality ovality position

Weld report

The Geopig system measures with the weld detect sensors each girth weld.

These welds are used in the database as primary identifiers and in the

kinematic analysis as boundary points. The WELDREPT program gives a

listing of all the welds, the run time when they were detected in seconds, and

the chainage in meters.

The valves (V), the start of heavy-wall sections (SH) and the end of heavy-

wall sections (EH) are identified in the Weld Number column:

Weld Time Chainage Chainage Length Length

number (sec) (m) (ft) (m) (ft)

Overview functions

Dent

The drag menu Dent on the main menu allows the number and extent of

the dents on the database to be summarized graphically. The chainage or time,

the computed out-of-roundness (including dent height less average ovality),

and the lengths of the dents, are summarized graphically. The welds, thick-

wall sections, and valves are identified on the display. The detail display can

be used to zoom-in on an area in the main display. The facility to locate a dent

and then exit to the analysis program allows rapid evaluation of the feature.

The width in time or metres of the display may be selected for either the

Dent or Curve mode. The minimum ovality or dent depth and minimum

length in scan lines may be selected as a criterion for those features that are

included in the summary.

Curve

As part of the Dent mode there is also the ability to plot the curvature of

the pipeline. The ratio of the detected bend in the pipeline to the pipeline

radius is indicated as potential strain according to the formula:

352