Page 413 - Pipeline Pigging Technology

P. 413

Pipeline Pigging Technology

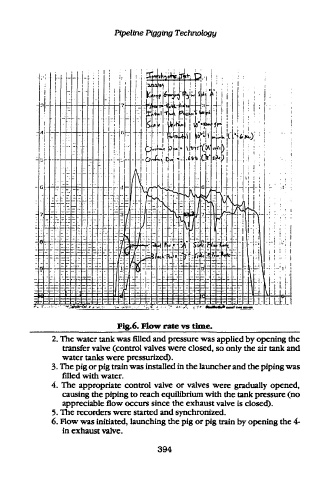

Fig.6. Flow rate vs time.

2. The water tank was filled and pressure was applied by opening the

transfer valve (control valves were closed, so only the air tank and

water tanks were pressurized).

3. The pig or pig train was installed in the launcher and the piping was

filled with water.

4. The appropriate control valve or valves were gradually opened,

causing the piping to reach equilibrium with the tank pressure (no

appreciable flow occurs since the exhaust valve is closed).

5. The recorders were started and synchronized.

6. Flow was initiated, launching the pig or pig train by opening the 4-

in exhaust valve.

394