Page 121 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 121

5/98 Design Index

for external loads

Wall thickness required

for internal pressure

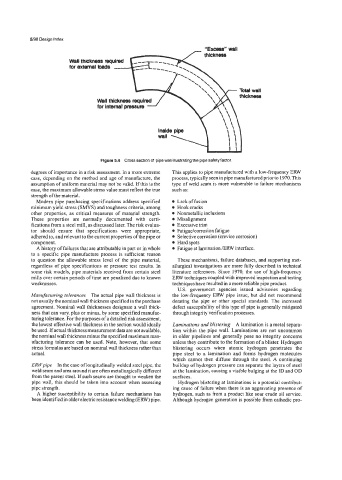

Figure 5.4 Cross section of pipe wall illustrating the pipe safetyfactor.

degrees of importance in a risk assessment. In a more extreme This applies to pipe manufactured with a low-frequency ERW

case, depending on the method and age of manufacture, the process, typically seen in pipe manufactured prior to 1970. Thls

assumption of uniform material may not be valid. If this is the type of weld seam is more vulnerable to failure mechanisms

case, the maximum allowable stress value must reflect the true such as:

strength of the material.

Modern pipe purchasing specifications address specified Lack of fusion

minimum yield stress (SMYS) and toughness criteria, among Hookcracks

other properties, as critical measures of material strength. Nonmetallic inclusions

These properties are normally documented with certi- Misalignment

fications from a steel mill, as discussed later. The risk evalua- Excessive trim

tor should ensure that specifications were appropriate, Fatigue/corrosion fatigue

adhered to, and relevant to the current properties ofthe pipe or Selective corrosion (crevice corrosion)

component. Hardspots

A history of failures that are attributable in part or in whole Fatigue at lamination ERW interface.

to a specific pipe manufacture process is sufficient reason

to question the allowable stress level of the pipe material, These mechanisms, failure databases, and supporting met-

regardless of pipe specifications or pressure test results. In allurgical investigations are more fully described in technical

some risk models, pipe materials received from certain steel literature references. Since 1970, the use of high-frequency

mills over certain periods of time are penalized due to known ERW techniques coupled with improved inspection and testing

weaknesses. techniques have resulted in a more reliable pipe product.

U.S. government agencies issued advisories regarding

Manufacturing tolerances The actual pipe wall thickness is the low-frequency ERW pipe issue, but did not recommend

not usually the nominal wall thickness specified in the purchase derating the pipe or other special standards. The increased

agreement. Nominal wall thicknesses designate a wall thick- defect susceptibility of this type of pipe is generally mitigated

ness that can vary, plus or minus, by some specified manufac- through integrity verification processes.

turing tolerance. For the purposes of a detailed risk assessment,

the lowest effective wall thickness in the section would ideally Laminations and blistering A lamination is a metal separa-

be used. If actual thickness measurement data are not available, tion within the pipe wall. Laminations are not uncommon

the nominal wall thickness minus the specified maximum man- in older pipelines and generally pose no integrity concerns

ufacturing tolerance can be used. Note, however, that some unless they contribute to the formation of a blister. Hydrogen

stress formulas are based on nominal wall thickness rather than blistering occurs when atomic hydrogen penetrates the

actual. pipe steel to a lamination and forms hydrogen molecules

which cannot then diffuse through the steel. A continuing

ERWpipe In the case of longitudinally welded steel pipe, the buildup of hydrogen pressure can separate the layers of steel

weld seam and area around it are often metallurgically different at the lamination, causing a visible bulging at the ID and OD

from the parent steel. If such seams are thought to weaken the surfaces.

pipe wall, this should be taken into account when assessing Hydrogen blistering at laminations is a potential contribut-

pipe strength. ing cause of failure when there is an aggravating presence of

A higher susceptibility to certain failure mechanisms has hydrogen, such as from a product like sour crude oil service.

been identified in older electric resistance welding (ERW) pipe. Although hydrogen generation is possible from cathodic pro-