Page 22 - Pipeline Rules of Thumb Handbook

P. 22

General Information 9

Strength and weight of popular wire rope

The following tables give the breaking strength for wire Conversion factors for wire rope of other

rope of popular construction made of improved plow steel. construction

6 ¥ 19 To apply the above table to wire rope of other construction,

multiply by the following factors:

SIZE Breaking Strength Weight

1 Wire Rope Construction 6 ¥ 19 6 ¥ 29 6 ¥ 37 18 ¥ 7

/ 4 5,480 0.10

5

/ 16 8,520 0.16

3 Strength Factors 1.00 0.96 0.95 0.92

/ 8 12,200 0.23

7

/ 16 16,540 0.31

1 Weight Factors 1.00 0.97 0.97 1.08

/ 2 21,400 0.40

9

/ 16 27,000 0.51

5

/ 8 33,400 0.63

3 Example. Find the breaking strength of 6 ¥ 29 improved

/ 4 47,600 0.90

7 plow steel wire rope two inches in diameter.

/ 8 64,400 1.23

1 83,600 1.60

1 Strength = 320,000 ¥ 0.96 = 307,000lb

1 / 8 105,200 2.03

1

1 / 4 129,200 2.50

3 The weight can be found the same way.

1 / 8 155,400 3.03

1

1 / 2 184,000 3.60

5

1 / 8 214,000 4.23

3

1 / 4 248,000 4.90

7

1 / 8 282,000 5.63

2 320,000 6.40

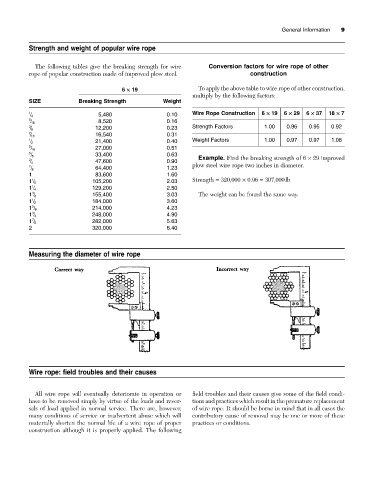

Measuring the diameter of wire rope

Wire rope: field troubles and their causes

All wire rope will eventually deteriorate in operation or field troubles and their causes give some of the field condi-

have to be removed simply by virtue of the loads and rever- tions and practices which result in the premature replacement

sals of load applied in normal service. There are, however, of wire rope. It should be borne in mind that in all cases the

many conditions of service or inadvertent abuse which will contributory cause of removal may be one or more of these

materially shorten the normal life of a wire rope of proper practices or conditions.

construction although it is properly applied. The following