Page 429 - Pipelines and Risers

P. 429

396 Chapier 21

- Materials

- Installation requirements

- Fabrication requirements

- Inspection and maintenance

- Engineering costs

21.2.2 Currently Used Design Criteria

The riser codes that are used in Norway for metallic risers are taken from regulations issued

by the Norwegian Petroleum Directorate (NPD). Both the Snorre and the Heidrun TLP risers

have been designed on that basis.

For internal overpressure design, the design checks recommended in the guideline or

equivalently the allowable stress method, where the maximum allowable stress is given as a

fraction of the Specified Minimum Yield Strength (SMYS), see Table 21.1 below. Note that

for yield strength above 490 MPa the lesser of SMYS or of the Minimum Specified Tensile

Strength (SMTS) divided by 1.2 is used. The stresses are calculated based on the minimum

wall thickness taking into account corrosion allowance and fabrication tolerances.

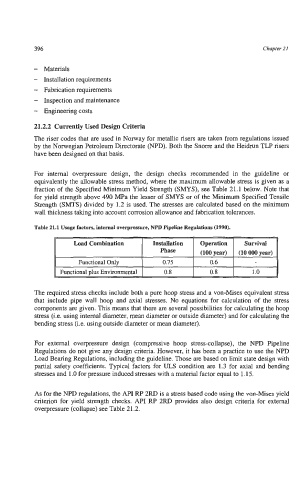

Table 21.1 Usage factors, internal overpressure, NPD Pipeline Regulations (1990).

(100 vear) I (10 sumva' vear) I

Load Combination Installation Operation

Phase OOO

Functional Only 0.75 0.6

1.0

The required stress checks include both a pure hoop stress and a von-Mises equivalent stress

that include pipe wall hoop and axial stresses. No equations for calculation of the stress

components are given. This means that there are several possibilities for calculating the hoop

stress (i.e. using internal diameter, mean diameter or outside diameter) and for calculating the

bending stress (i.e. using outside diameter or mean diameter).

For external overpressure design (compressive hoop stress-collapse), the NPD Pipeline

Regulations do not give any design criteria. However, it has been a practice to use the NPD

Load Bearing Regulations, including the guideline. Those are based on limit state design with

partial safety coefficients. Typical factors for ULS condition are 1.3 for axial and bending

stresses and 1.0 for pressure induced stresses with a material factor equal to 1.15.

As for the NPD regulations, the API RP 2RD is a stress based code using the von-Mises yield

criterion for yield strength checks. API RP 2RD provides also design criteria for external

overpressure (collapse) see Table 21.2.