Page 431 - Pipelines and Risers

P. 431

398 Chapier 21

- Yielding and material deterioration due to high temperature

- Collapse due to high external pressure

- Riser collision and interference in arrays

1. Serviceability limit state (SLS)

Referring to contact between riser in a group or in parallel or between risers and floaters due

to wave motion, out of roundness, etc. Serviceability requirements may also be imposed to

avoid permanent deformation of the tubes, which would hamper pigging or other operation of

equipment in the pipes.

2. Ultimate limit state (VLS)

Referring to the failures due to yielding, buckling, bursting, collapse and loss of equilibrium

of the pipe cross-section. Yielding failure mode for risers is treated as ULS even though it

will not result in immediate failure. Because risers are usually made of high strength materials

(steel or titanium) which do not have a considerable strain hardening effect. For this reason,

the yield strength may be very close to the ultimate tensile strength.

3. Fatigue limit state (ns)

Referring to the fatigue failure due to dynamic cycle loading effects. Three major issues

causing fatigue damage of risers include:

- 1st order wave loading and associated floater motion

- 2nd order floater motion

- Vortex induced vibrations (VIV) due to current

4. Progress collapse limit state (PLS)

Referring to the failure initiated by accidental events such as the damage caused by impacts of

dropped objects, abnormal corrosion, loss of pretension, mooring line failure, floater damage,

abnormal environmental conditions, etc.

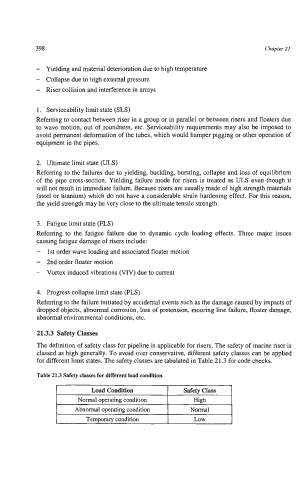

21.3.3 Safety Classes

The definition of safety class for pipeline is applicable for risers. The safety of marine riser is

classed as high generally. To avoid over conservative, different safety classes can be applied

for different limit states. The safety classes are tabulated in Table 21.3 for code checks.

Load Condition Safety Class

Normal operating condition High

Abnormal operating condition Normal

Temporary condition LOW