Page 530 - Pipelines and Risers

P. 530

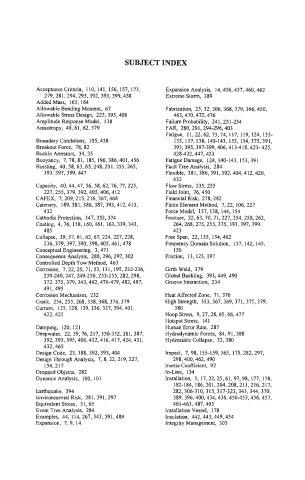

Acceptance Criteria, 110, 141, 156, 157, 173, Expansion Analysis, 14,456,457,460,462

279,281,294,295,392,393,399,458 Extreme Storm, 389

Added Mass, 163,164

Allowable Bending Moment, 67 Fabrication, 25,32,306,368,379,396,450,

Allowable Stress Design, 225,395,408 463,470,472,476

Amplitude Response Model, 138 Failure Probability, 241,251-254

Anisotropy, 40,61,62,379 FAR, 280,291,294-296,403

Fatigue, 11,22,62,73,74,117,119,124,133-

Boundary Conditions, 105,438 135,137,138,140-143,153,154,375,391,

Breakout Force, 78,82 393,395,397-399,406,413418,423- 425,

Buckle Arrestors, 34,35 428432,447,453

Buoyancy, 7,78,81, 185,196,386,401,456 Fatigue Damage, 124, 140-143,153,391

Bursting, 40, 58,63,65,248,251,255,265, Fault Tree Analysis, 284

393,397,399,447 Flexible, 381,386,391,392,404,412,420,

432

Capacity, 40,44,47,56,58,62,76,77,225, Flow Stress, 235,255

227,255,379,392,405,406,412 Field Joint, 76,450

CAPEX, 7,209,215,216,367,468 Financial Risk, 278,282

Catenary, 189,381,386,387,393,412,413, Finite Element Method, 7,22, 106,227

432 Force Model, 137,138,144,154

Cathodic Protection, 347,352,374 Fracture, 22,63,70,71,227,254,258,262,

Coating, 4,76, 158, 160, 161, 163,339,343, 264,268,275,255,375,393,397,399,

485 423

Collapse, 39,57,61,62,67,224,227,228, Free Span, 22, 135,154,462

236,379,397,390,398,405,461,478 Frequency Domain Solution, 137, 142, 145,

Conceptual Engineering, 3,471 I50

Consequence Analysis, 288,296,297,302 Friction, 13, 123, 197

Controlled Depth Tow Method, 463

Corrosion, 7,22,25,71,53, 131, 195,232-236, Girth Weld, 379

239-240,247,249-250,253-255,282,298, Global Buckling, 393,449,490

372,375,379,343,462,476479,482,487, Groove Interaction, 234

491,495

Corrosion Mechanism, 232 Heat Affected Zone, 7 1,376

Crack, 254,255,268,338,368,376,379 High Strength, 353,367,369,371,375,379,

Current, 125, 128, 139,336,337,394,401, 380

422,425 Hoop Stress, 9,27,28,65,66,477

Hotspot Stress, 141

Damping, 120, 121 Human Error Rate, 287

Deepwater, 22,39,76,217,350-352,381,387, Hydrodynamic Forces, 84,91,388

392,393,395,406,412,416,417,424,431, Hydrostatic Collapse, 32,380

432,465

Design Code, 23,388,392,393,404 Impact, 7, 98, 155-159, 165, 175,282,297,

Design Through Analysis, 7, 8,22,219,227, 298,400,462,490

154,217 Inertia Coefficient, 92

Dropped Objects, 282 In-Line, 134

Dynamic Analysis, 100, 101 Installation, 3, 17,22,25,61,97,98, 177,178,

182-1 84, 186,201,204,208,211,216,2 17,

Earthquake, 394 282,306-310,315,317-323,343,344,370,

Environmental Risk, 281,291,297 389,396,400,434,436,450-453,456,457,

Equivalent Stress, 3 1,65 461-463,487,495

Event Tree Analysis, 284 Installation Vessel, 178

Examples, 44, 114,267,343,391,489 Insulation, 442,443,449,454

Expansion, 7,9, 14 Integrity Management, 303