Page 531 - Pipelines and Risers

P. 531

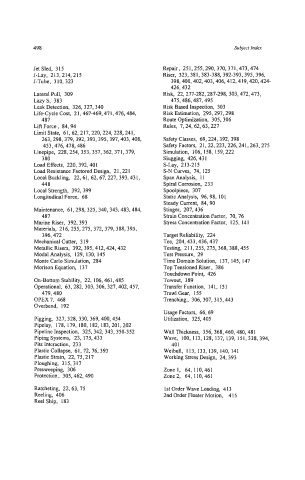

498 Subject Index

Jet Sled, 315 Repair, 251,255,290,370,371,473,474

ELay, 213,214,215 Riser, 323,381,383-388,392-393,395,396,

J-Tube, 310,323 398,400,402,403,406,412,419,420,424-

426,432

Lateral Pull, 309 Risk, 22,277-282,287-298,303,472,473,

LazyS, 383 475,486,487,495

Leak Detection, 326,327,340 Risk Based Inspection, 303

Life-Cycle Cost, 21,467-469,471,476,484, Risk Estimation, 295,297,298

487 Route Optimization, 305,306

Lift Force, 84,94 Rules, 7,24,62,63,227

Limit State, 61,62,217,220,224,228,241,

263,298,379,392,393,395,397,403,408, Safety Classes, 69,224,392,398

453,476,478,486 Safety Factors, 21,22,223,226,241,263,275

Linepipe, 228,254,353,357,362,371,379, Simulation, 106, 158, 159,222

380 Slugging, 426,43 1

Load Effects, 220,392,401 S-Lay, 213-215

Load Resistance Factored Design, 21,221 S-N Curves, 74,125

Local Buckling, 22,61,62,67,227,393,431, SpanAnalysis, I1

448 Spiral Corrosion, 233

Local Strength, 392,399 Spoolpiece, 307

Longitudinal Force, 68 Static Analysis, 96,98, 101

Steady Current, 84,90

Maintenance, 61,298,325,340,343,483,484, Stinger, 207,436

487 Strain Concentration Factor, 70,76

Marine Riser, 392,393 Stress Concentration Factor, 125, 141

Materials, 216,255,275,372,379,388,395,

396,472 Target Reliability, 224

Mechanical Cutter, 3 19 Tee, 204,433,436,437

Metallic Risers, 392,395,412,424,432 Testing, 21 1,255,275,368,388,455

Modal Analysis, 129, 130, 145 Test Pressure, 29

Monte Carlo Simulation, 284 Time Domain Solution, 137,145,147

Morison Equation, 137 Top Tensioned Riser, 386

Touchdown Point, 426

On-Bottom Stability, 22, 106,461,485 Towout, 389

Operational, 63,282,303,306,327,402,457, Transfer Function, 14 1, I 5 1

479,480 Trawl Gear, 155

OPEX7, 468 Trenching, 306,307,315,443

Overbend. 192

Usage Factors, 66,69

Pigging, 327,328,330,369,400,454 Utilization, 325,405

Pipelay, 178, 179, 180, 182, 183,201,202

Pipeline Inspection, 325,342,343,350-352 Wall Thickness, 356,368,460,480,481

Piping Systems, 23, 175,433 Wave, 100,113, 128,137,139,151,338,394,

Pits Interaction, 233 40 1

Plastic Collapse, 61,72,76, 393 Weibull, 113, 133, 139, 140, 141

Plastic Strain, 22,75,217 Working Stress Design, 24,393

Ploughing, 315,317

Presweeping, 306 Zone 1, 64,110,461

Protection, 305,462,490 Zone 2, 64,110,461

Ratcheting, 22,63, 75 1 st Order Wave Loading, 4 I3

Reeling, 406 2nd Order Floater Motion. 415

Reel Ship, 183