Page 141 - Plant design and economics for chemical engineers

P. 141

116 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

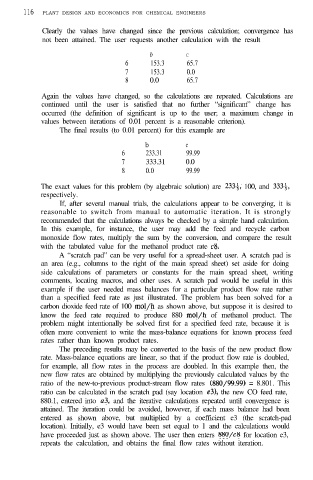

Clearly the values have changed since the previous calculation; convergence has

not been attained. The user requests another calculation with the result

b C

6 153.3 65.7

7 153.3 0.0

8 0.0 65.7

Again the values have changed, so the calculations are repeated. Calculations are

continued until the user is satisfied that no further “significant” change has

occurred (the definition of significant is up to the user; a maximum change in

values between iterations of 0.01 percent is a reasonable criterion).

The final results (to 0.01 percent) for this example are

b c

6 233.31 99.99

7 333.31 0.0

8 0.0 99.99

The exact values for this problem (by algebraic solution) are 233$, 100, and 3334,

respectively.

If, after several manual trials, the calculations appear to be converging, it is

reasonable to switch from manual to automatic iteration. It is strongly

recommended that the calculations always be checked by a simple hand calculation.

In this example, for instance, the user may add the feed and recycle carbon

monoxide flow rates, multiply the sum by the conversion, and compare the result

with the tabulated value for the methanol product rate c8.

A “scratch pad” can be very useful for a spread-sheet user. A scratch pad is

an area (e.g., columns to the right of the main spread sheet) set aside for doing

side calculations of parameters or constants for the main spread sheet, writing

comments, locating macros, and other uses. A scratch pad would be useful in this

example if the user needed mass balances for a particular product flow rate rather

than a specified feed rate as just illustrated. The problem has been solved for a

carbon dioxide feed rate of 100 mol/h as shown above, but suppose it is desired to

know the feed rate required to produce 880 mol/h of methanol product. The

problem might intentionally be solved first for a specified feed rate, because it is

often more convenient to write the mass-balance equations for known process feed

rates rather than known product rates.

The preceding results may be converted to the basis of the new product flow

rate. Mass-balance equations are linear, so that if the product flow rate is doubled,

for example, all flow rates in the process are doubled. In this example then, the

new flow rates are obtained by multiplying the previously calculated values by the

ratio of the new-to-previous product-stream flow rates (880/99.99) = 8.801. This

ratio can be calculated in the scratch pad (say location e3), the new CO feed rate,

880.1, entered into a3, and the iterative calculations repeated until convergence is

attained. The iteration could be avoided, however, if each mass balance had been

entered as shown above, but multiplied by a coefficient e3 (the scratch-pad

location). Initially, e3 would have been set equal to 1 and the calculations would

have proceeded just as shown above. The user then enters 88O/c8 for location e3,

repeats the calculation, and obtains the final flow rates without iteration.