Page 145 - Plant design and economics for chemical engineers

P. 145

120 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

n

By-products

Condensed

steam

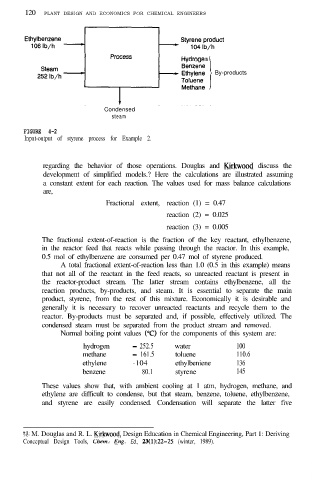

FIGURE 4-2

Input-output of styrene process for Example 2.

regarding the behavior of those operations. Douglas and Kirkwood discuss the

development of simplified models.? Here the calculations are illustrated assuming

a constant extent for each reaction. The values used for mass balance calculations

are,

Fractional extent, reaction (1) = 0.47

reaction (2) = 0.025

reaction (3) = 0.005

The fractional extent-of-reaction is the fraction of the key reactant, ethylbenzene,

in the reactor feed that reacts while passing through the reactor. In this example,

0.5 mol of ethylbenzene are consumed per 0.47 mol of styrene produced.

A total fractional extent-of-reaction less than 1.0 (0.5 in this example) means

that not all of the reactant in the feed reacts, so unreacted reactant is present in

the reactor-product stream. The latter stream contains ethylbenzene, all the

reaction products, by-products, and steam. It is essential to separate the main

product, styrene, from the rest of this mixture. Economically it is desirable and

generally it is necessary to recover unreacted reactants and recycle them to the

reactor. By-products must be separated and, if possible, effectively utilized. The

condensed steam must be separated from the product stream and removed.

Normal boiling point values (OC) for the components of this system are:

hydrogen - 252.5 water 100

methane - 161.5 toluene 110.6

ethylene -104 ethylbeniene 136

benzene 80.1 styrene 145

These values show that, with ambient cooling at 1 atm, hydrogen, methane, and

ethylene are difficult to condense, but that steam, benzene, toluene, ethylbenzene,

and styrene are easily condensed. Condensation will separate the latter five

tJ. M. Douglas and R. L. Kirkwood, Design Education in Chemical Engineering, Part 1: Deriving

Conceptual Design Tools, Gem. Eng. Ed., 23(1):22-25 (winter, 1989).