Page 147 - Plant design and economics for chemical engineers

P. 147

122 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

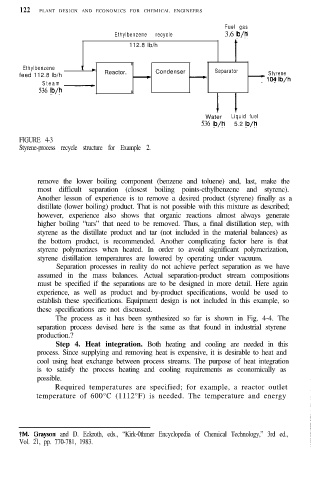

Fuel gas

Ethylbenzene recycle 3.6 lb/h

112.8 lb/h

t

1

Ethylbenzene T * Condenser Separator

feed 112.8 lb/h Reactor. - - Styrene

S t e a m - -104lb/h

536 lb/h A

I 1

Water Liquid fuel

536 lb/h 5.2 lb/h

FIGURE 4-3

Styrene-process recycle structure for Example 2.

remove the lower boiling component (benzene and toluene) and, last, make the

most difficult separation (closest boiling points-ethylbenzene and styrene).

Another lesson of experience is to remove a desired product (styrene) finally as a

distillate (lower boiling) product. That is not possible with this mixture as described;

however, experience also shows that organic reactions almost always generate

higher boiling “tars” that need to be removed. Thus, a final distillation step, with

styrene as the distillate product and tar (not included in the material balances) as

the bottom product, is recommended. Another complicating factor here is that

styrene polymerizes when heated. In order to avoid significant polymerization,

styrene distillation temperatures are lowered by operating under vacuum.

Separation processes in reality do not achieve perfect separation as we have

assumed in the mass balances. Actual separation-product stream compositions

must be specified if the separations are to be designed in more detail. Here again

experience, as well as product and by-product specifications, would be used to

establish these specifications. Equipment design is not included in this example, so

these specifications are not discussed.

The process as it has been synthesized so far is shown in Fig. 4-4. The

separation process devised here is the same as that found in industrial styrene

production.?

Step 4. Heat integration. Both heating and cooling are needed in this

process. Since supplying and removing heat is expensive, it is desirable to heat and

cool using heat exchange between process streams. The purpose of heat integration

is to satisfy the process heating and cooling requirements as economically as

possible.

Required temperatures are specified; for example, a reactor outlet

temperature of 600°C (1112°F) is needed. The temperature and energy

tM. Grayson and D. Eckroth, eds., “Kirk-0thmer Encyclopedia of Chemical Technology,” 3rd ed.,

Vol. 21, pp. 770-781, 1983.