Page 222 - Plant design and economics for chemical engineers

P. 222

Dire-3

Direct Dweci Direct Dwect labor Dwect

material labor total cost mOtk?rlOl totol cost

E+M) M‘ (E + M •t- ML) (E+M) ML (E + A:’ + M,.)

E = F.0.B equipment 1 0 0 . 0 E = F.0.B equipment

Plping modu

/ factor / Concrete

Bare Concrete (x3.4 Bore Steel

steel

module Instruments M module Instruments M chct

factor

factor Electrlcol Dwect Electrical cost

(X 2.5)5) lnsulot1on cost (x? r18) Insulohon foCtOr*

ioctor.

t-+~ot+&+

Pomt (x 2.20) Pomt M.61)

M Oter iol M Clter 101

foe :tot :tor

(xl .6: 2) 1:.27

L

= 0.27 Indirect

f o c t a

M.29)

l Field instollohon *Field instollotlon

208.1

L : Total bore module I- + Bare module -A

Conhngency and fee (18 %)- 53.1 Contingency ond fee (lB%)- 37.5

Total module cost Total module cost

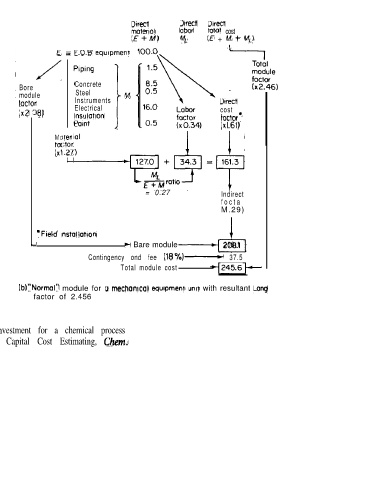

(a)“Normcl” module for o chemical process umt wth resultant Long (b)“Normol” module for (1 mechanical equpment umt with resultant Lang

factor of 3.482 factor of 2.456

FIGURE 6-6

Example of a “normal” module as applied for estimating capital investment for a chemical process

and a mechanical equipment unit. [Adapted from K. M. Guthrie, Capital Cost Estimating, Chem.

Eng., 76(6):114 (March 24, 1969j.l