Page 243 - Plant design and economics for chemical engineers

P. 243

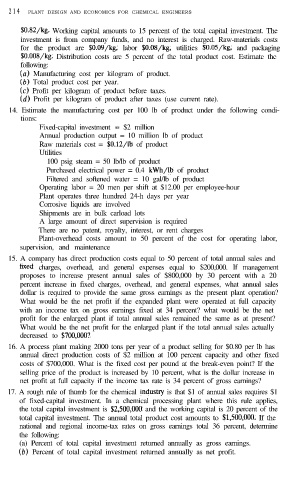

2 1 4 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

$0.82/kg. Working capital amounts to 15 percent of the total capital investment. The

investment is from company funds, and no interest is charged. Raw-materials costs

for the product are $O.O9/kg, labor $O.O8/kg, utilities $O.O5/kg, and packaging

$O.O08/kg. Distribution costs are 5 percent of the total product cost. Estimate the

following:

(a) Manufacturing cost per kilogram of product.

(b) Total product cost per year.

(c> Profit per kilogram of product before taxes.

(d) Profit per kilogram of product after taxes (use current rate).

14. Estimate the manufacturing cost per 100 lb of product under the following condi-

tions:

Fixed-capital investment = $2 million

Annual production output = 10 million lb of product

Raw materials cost = $O.l2/lb of product

Utilities

100 psig steam = 50 lb/lb of product

Purchased electrical power = 0.4 kWh/lb of product

Filtered and softened water = 10 gal/lb of product

Operating labor = 20 men per shift at $12.00 per employee-hour

Plant operates three hundred 24-h days per year

Corrosive liquids are involved

Shipments are in bulk carload lots

A large amount of direct supervision is required

There are no patent, royalty, interest, or rent charges

Plant-overhead costs amount to 50 percent of the cost for operating labor,

supervision, and maintenance

15. A company has direct production costs equal to 50 percent of total annual sales and

tixed charges, overhead, and general expenses equal to $200,000. If management

proposes to increase present annual sales of $800,000 by 30 percent with a 20

percent increase in fixed charges, overhead, and general expenses, what annual sales

dollar is required to provide the same gross earnings as the present plant operation?

What would be the net profit if the expanded plant were operated at full capacity

with an income tax on gross earnings fixed at 34 percent? what would be the net

profit for the enlarged plant if total annual sales remained the same as at present?

What would be the net profit for the enlarged plant if the total annual sales actually

decreased to $700,000?

16. A process plant making 2000 tons per year of a product selling for $0.80 per lb has

annual direct production costs of $2 million at 100 percent capacity and other fixed

costs of $700,000. What is the fixed cost per pound at the break-even point? If the

selling price of the product is increased by 10 percent, what is the dollar increase in

net profit at full capacity if the income tax rate is 34 percent of gross earnings?

17. A rough rule of thumb for the chemical industry is that $1 of annual sales requires $1

of fixed-capital investment. In a chemical processing plant where this rule applies,

the total capital investment is $2,500,000 and the working capital is 20 percent of the

total capital investment. The annual total product cost amounts to $1,500,000. If the

national and regional income-tax rates on gross earnings total 36 percent, determine

the following:

(a) Percent of total capital investment returned annually as gross earnings.

(b) Percent of total capital investment returned annually as net profit.