Page 38 - Plant design and economics for chemical engineers

P. 38

PROCESS DESIGN DEVELOPMENT 21

Stack

Exit gas to stack or power recovery

Ud

Cooler condensers

I

Bubble-cap

absorption

tower with

interplote

Platinu cooling

filter

+

Cxidotion

chamber

Mixing

chamber

B lwer T_

rt cry I- 17 60-65 wt. %

nitric acid

to storage

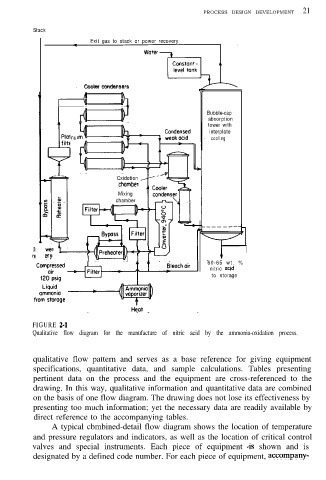

FIGURE 2-1

Qualitative flow diagram for the manufacture of nitric acid by the ammonia-oxidation process.

qualitative flow pattern and serves as a base reference for giving equipment

specifications, quantitative data, and sample calculations. Tables presenting

pertinent data on the process and the equipment are cross-referenced to the

drawing. In this way, qualitative information and quantitative data are combined

on the basis of one flow diagram. The drawing does not lose its effectiveness by

presenting too much information; yet the necessary data are readily available by

direct reference to the accompanying tables.

A typical cbmbined-detail flow diagram shows the location of temperature

and pressure regulators and indicators, as well as the location of critical control

valves and special instruments. Each piece of equipment 4s shown and is

designated by a defined code number. For each piece of equipment, accompany-