Page 39 - Plant design and economics for chemical engineers

P. 39

22 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

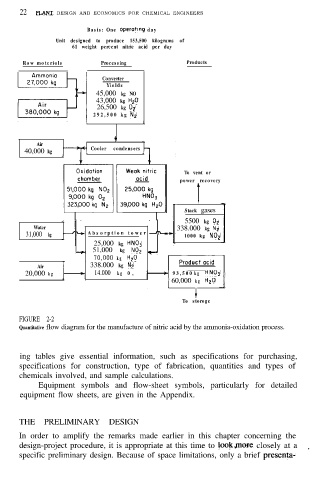

Basis: One operatrng day

Unit designed to produce 153,500 kilograms of

61 weight percent nitric acid per day

Row moteriols Processing Products

Converter

Yields

45,000 kg NO

43,000 kg Hz0

26,500 kg O2

2 9 2 , 5 0 0 k g N,

L 1

.

Air

40,000 kg Cooler condensers

To vent or

power recovery

t I

Stack gases

5500 kg O2

Water - 338.000 kg N2

31,000 kg 4 A b s o r p t i o n t o w e r 2~ 1000 kg NO2

25,000 kg HNO,

- 51,000 kg NO2 -

70,000 k g H,O

Air 338.000 kg N2

20,000 k g 14.000 k g 0 , 9 3 , 5 0 0 k g HNO,

60,000 k g H,O

+

To storoge

FIGURE 2-2

Quantitative flow diagram for the manufacture of nitric acid by the ammonia-oxidation process.

ing tables give essential information, such as specifications for purchasing,

specifications for construction, type of fabrication, quantities and types of

chemicals involved, and sample calculations.

Equipment symbols and flow-sheet symbols, particularly for detailed

equipment flow sheets, are given in the Appendix.

THE PRELIMINARY DESIGN

In order to amplify the remarks made earlier in this chapter concerning the

design-project procedure, it is appropriate at this time to lookmore closely at a I

specific preliminary design. Because of space limitations, only a brief presenta-