Page 44 - Plant design and economics for chemical engineers

P. 44

PROCESS DESIGN DEVELOPMENT 27

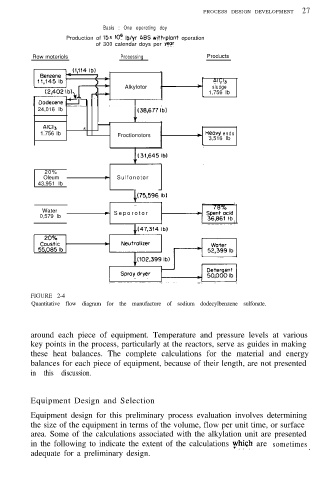

Basis : One operoting doy

Production of 15~ lo6 Ib/yr BBS withaplont operation

of 300 calendar doys per yeor

Row moteriols Processing Products

AICI,

Alkylotor sludge

1,756 lb

24,016 lb

-

AIC13 t

1.756 lb Froctionotors Heavy ends

3,516 lb

20%

Oleum * Sulfonotor

43,951 lb

1(75,596 lb)

Water * S e p o r o t o r

0,579 lb

1t47.314 lb)

FIGURE 2-4

Quantitative flow diagram for the manufacture of sodium dodecylbenzene sulfonate.

around each piece of equipment. Temperature and pressure levels at various

key points in the process, particularly at the reactors, serve as guides in making

these heat balances. The complete calculations for the material and energy

balances for each piece of equipment, because of their length, are not presented

in this discussion.

Equipment Design and Selection

Equipment design for this preliminary process evaluation involves determining

the size of the equipment in terms of the volume, flow per unit time, or surface

area. Some of the calculations associated with the alkylation unit are presented

in the following to indicate the extent of the calculations yhich are sometimes .

adequate for a preliminary design.