Page 41 - Plant design and economics for chemical engineers

P. 41

24 PLANT DESIGN AND ECONOMICS FOR CHEM!CAL ENGINEERS

Dodecene

R e a c t 0r

(olkylot or)

S etttler .L L- L-

Aicl, sludge

- -NaOH Spray

Yiactor I \ I

Y

Detergent

product

“Builders”

H e a v y Spent

alkyloted acid

h y d r o c a r b o n s

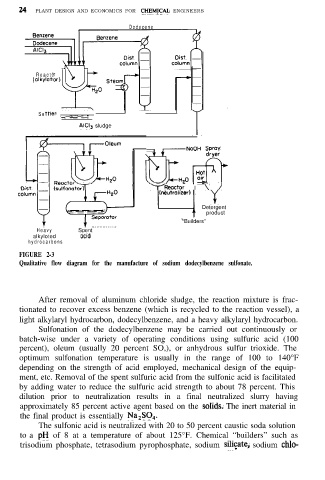

FIGURE 2-3

Qualitative flow diagram for the manufacture of sodium dodecylbenzene sulfonate.

After removal of aluminum chloride sludge, the reaction mixture is frac-

tionated to recover excess benzene (which is recycled to the reaction vessel), a

light alkylaryl hydrocarbon, dodecylbenzene, and a heavy alkylaryl hydrocarbon.

Sulfonation of the dodecylbenzene may be carried out continuously or

batch-wise under a variety of operating conditions using sulfuric acid (100

percent), oleum (usually 20 percent SO,), or anhydrous sulfur trioxide. The

optimum sulfonation temperature is usually in the range of 100 to 140°F

depending on the strength of acid employed, mechanical design of the equip-

ment, etc. Removal of the spent sulfuric acid from the sulfonic acid is facilitated

by adding water to reduce the sulfuric acid strength to about 78 percent. This

dilution prior to neutralization results in a final neutralized slurry having

approximately 85 percent active agent based on the sohds. The inert material in

the final product is essentially Na,SO,.

The sulfonic acid is neutralized with 20 to 50 percent caustic soda solution

to a pH of 8 at a temperature of about 125°F. Chemical “builders” such as

trisodium phosphate, tetrasodium pyrophosphate, sodium silitate, sodium chlo-