Page 50 - Plant design and economics for chemical engineers

P. 50

PROCESS DESIGN DEVELOPMENT 33

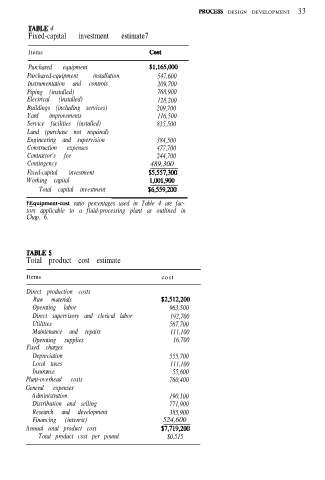

TABLE 4

Fixed-capital investment estimate7

Items cost

Purchased equipment $1,165,000

Purchased-equipment installation 547,600

Instrumentation and controls 209,700

Piping (installed) 768,900

Electrical (installed) 128,200

Buildings (including services) 209,700

Yard improvements 116,500

Service facilities (installed) 815,500

Land (purchase not required)

Engineering and supervision 384,500

Construction expenses 477,700

Contractor’s fee 244,700

Contingency 489,300

Fixed-capital investment $5,557,300

Working capital wan

Total capital investment $6,559,200

tEquipment-cost ratio percentages used in Table 4 are fac-

tors applicable to a fluid-processing plant as outlined in

Chap. 6.

TABLE 5

Total product cost estimate

Items cost

Direct production costs

Raw materials $2,512,200

Operating labor 963,500

Direct supervisory and clerical labor 192,700

Utilities 567,700

Maintenance and repairs 111,100

Operating supplies 16,700

Fixed charges

Depreciation 555,700

Local taxes 111,100

Insurance 55,600

Plant-overhead costs 760,400

General expenses

Administration 190,100

Distribution and selling 771,900

Research and development 385,900

Financing (interest) 524,600

Annual total product cost $7,719,200

Total product cost per pound $0.515