Page 54 - Plant design and economics for chemical engineers

P. 54

PROCESS DESIGN DEVELOPMENT 37

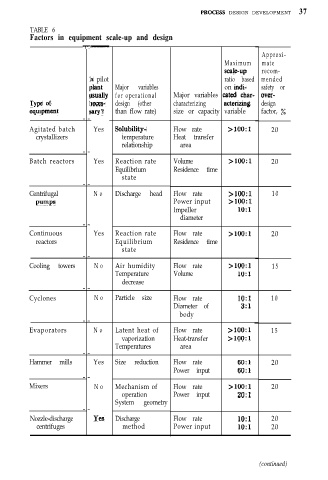

TABLE 6

Factors in equipment scale-up and design

l-

Approxi-

Maximum mate

SCalkWlp recom-

1:s pilot ratio based mended

1 slant Major variables on indi- safety or

Iusually for operational Major variables cated char- over-

Type of 1IeceS- design (other characterizing acterizing design

6 Zlly? than flow rate) size or capacity variable factor, %

- -

Agitated batch Yes Solubility- Flow rate >lCO:l 20

crystallizers temperature Heat transfer

relationship area

- -

Batch reactors Yes Reaction rate Volume >lOO:l 20

Equilibrium Residence time

state

- -

Centrifugal N o Discharge head Flow rate >lOO:l 1 0

pump* Power input >lOO:l

Impeller 1O:l

diameter

- -

Continuous Yes Reaction rate Flow rate >lOO:l 20

reactors Equilibrium Residence time

state

- -

Cooling towers N o Air humidity Flow rate >lOO:l 1 5

Temperature Volume 1O:l

decrease

- -

Cyclones N o Particle size Flow rate IO:1 1 0

Diameter of 3:l

body

- -

Evaporators N o Latent heat of Flow rate >lOO:l 1 5

vaporization Heat-transfer >lOO:l

Temperatures area

- -

Hammer mills Yes Size reduction Flow rate 6O:l 20

Power input 6O:l

- -

Mixers N o Mechanism of Flow rate >lOO:l 20

operation Power input 2O:l

System geometry

- -

Nozzle-discharge YeS Discharge Flow rate 1O:l 20

centrifuges method Power input 1O:l 20

(continued)