Page 58 - Plant design and economics for chemical engineers

P. 58

PROCESS DESIGN DEVELOPMENT 41

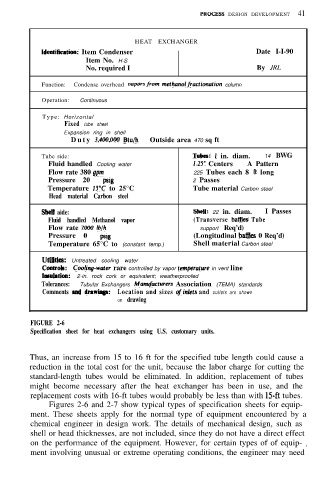

HEAT EXCHANGER

Identitication: Item Condenser Date I-I-90

Item No. H-S

No. required I By JRL

Function: Condense overhead uuporsfiom methanolfiactionafion column

Operation: Continuous

Type: Horizontal

Fixed tube sheet

Expansion ring in shell

D u t y 3,400,OOO Btu/h Outside area 470 sq ft

Tube side: Tubea: I in. diam. 14 BWG

Fluid handled Cooling water J.25” Centers A Pattern

Flow rate 380 gpm 225 Tubes each 8 ft long

Pressure 20 psig 2 Passes

Temperature 15°C to 25°C Tube material Carbon steel

Head material Carbon steel

SbeU aide: SkII: 22 in. diam. I Passes

Fluid handled Methanol vapor (Transverse ballks Tube

Flow rate 7OtXJ lb/h support Req’d)

Pressure 0 psiki (Longitudinal bathes 0 Req’d)

Temperature 65°C to (constant temp.) Shell material Carbon steel

Utilities: Untreated cooling water

Controh: Cooling-warer rare controlled by vapor temperature in vent line

Imuhtion: 2-in. rock cork or equivalent; weatherproofed

Tolerances: Tubular Exchangers Manujiiturers Association (TEMA) standards

Comments and drawimp: Location and sizes o/inlets and outlets are shown

on drawing

FIGURE 2-6

Specification sheet for heat exchangers using U.S. customary units.

Thus, an increase from 15 to 16 ft for the specified tube length could cause a

reduction in the total cost for the unit, because the labor charge for cutting the

standard-length tubes would be eliminated. In addition, replacement of tubes

might become necessary after the heat exchanger has been in use, and the

replacement costs with 16-ft tubes would probably be less than with 15ft tubes.

Figures 2-6 and 2-7 show typical types of specification sheets for equip-

ment. These sheets apply for the normal type of equipment encountered by a

chemical engineer in design work. The details of mechanical design, such as

shell or head thicknesses, are not included, since they do not have a direct effect

on the performance of the equipment. However, for certain types of of equip- I

ment involving unusual or extreme operating conditions, the engineer may need