Page 56 - Plant design and economics for chemical engineers

P. 56

PROCESS DESlGN DEVELOPMENT 39

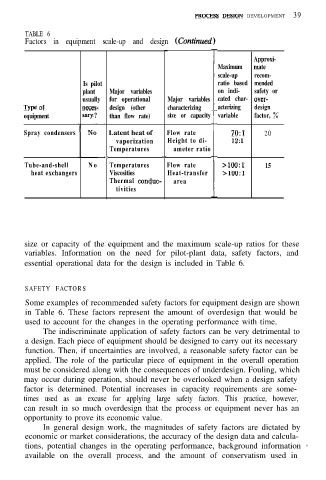

TABLE 6

Factors in equipment scale-up and design (C~rztinued)

Approxi-

Maximum mate

scale-up recom-

Is pilot ratio based mended

plant Major variables on indi- safety or

usually for operational Major variables cated char- over-

c

Type of ncces- design (other characterizing . acterizing design

equipment sary ? than flow rate) size or capacity variable factor, %

.

Spray condensers Latent heat of Flow rate 7O:l 20

vaporization Height to di- 12:l

Temperatures ameter ratio

_- ._

Tube-and-shell N o Temperatures Flow rate >lOO:l 15

heat exchangers Viscosities Heat-transfer >lOO:l

Thermal conduc- area .

tivities

size or capacity of the equipment and the maximum scale-up ratios for these

variables. Information on the need for pilot-plant data, safety factors, and

essential operational data for the design is included in Table 6.

SAFETY FACTORS

Some examples of recommended safety factors for equipment design are shown

in Table 6. These factors represent the amount of overdesign that would be

used to account for the changes in the operating performance with time.

The indiscriminate application of safety factors can be very detrimental to

a design. Each piece of equipment should be designed to carry out its necessary

function. Then, if uncertainties are involved, a reasonable safety factor can be

applied. The role of the particular piece of equipment in the overall operation

must be considered along with the consequences of underdesign. Fouling, which

may occur during operation, should never be overlooked when a design safety

factor is determined. Potential increases in capacity requirements are some-

times used as an excuse for applying large safety factors. This practice, however,

can result in so much overdesign that the process or equipment never has an

opportunity to prove its economic value.

In general design work, the magnitudes of safety factors are dictated by

economic or market considerations, the accuracy of the design data and calcula-

tions, potential changes in the operating performance, background information +

available on the overall process, and the amount of conservatism used in