Page 55 - Plant design and economics for chemical engineers

P. 55

38 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

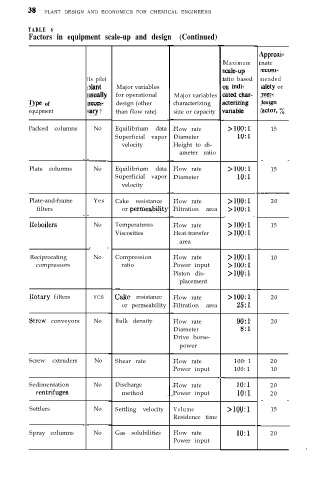

TABLE 6

Factors in equipment scale-up and design (Continued)

I jpproxi-

Maximum I nate

;cale-up I .ecom-

1 Is pilot atio based I nended

1 3Iant Major variables In indi- safety or

1 Jsually for operational Major variables zaated char- , 3ver-

Type of 1 leces- design (other characterizing lcterizing , jesign

equipment ‘ iary ? than flow rate) size or capacity variable I lador, %

Packed columns No Equilibrium data Flow rate >lOO:l 15

Superficial vapor Diameter 1O:l

velocity Height to di-

ameter ratio

- --. - -

Plate columns No Equilibrium data Flow rate >lOO:l 15

Superficial vapor Diameter 1O:l

velocity

.- -____

Plate-and-frame Yes Cake resistance Flow rate >lOO:l 20

filters or permeabilit) Filtration area >lOO:l

- - - -

llcboilers No Temperatures Flow rate >lOO:l 15

Viscosities Heat-transfer >lOO:l

area

- - - -

Reciprocating No Compression Flow rate >lOO:l 10

compressors ratio Power input >lOO:l

Piston dis- >lOO:l

placement

- .-

liotnry filters YCS Cake resistance Flow rate >lOO:l 20

or permeability Filtration area 25:l

Screw conveyors No Bulk density Flow rate 9O:l 20

Diameter 8:l

Drive horse-

power

Screw cxtruders No Shear rate Flow rate 100: 1 20

Power input 100: 1 10

_-

Sedimentation No Discharge Flow rate IO:1 20

centrifuges method Power input IO:1 20

- -

Settlers No Settling velocity Volume >lOO:l 15

Residence time

-_ .-

Spray columns No Gas solubilities Flow rate 1O:l 20

Power input

*