Page 59 - Plant design and economics for chemical engineers

P. 59

42 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

SIEVE-TRAY COLUMN

Identification: Item Date

Item No.

No. required B Y

Function:

Operation:

Materirk handled: Feed Overhead RepU.X Bottoms

Quantity

Composition

Temperature

Design data: No. of trays Reflux ratio

Pressure Tray spacing

Functional height Skirt height

Material of construction

Diameter: Liquid density lb/h3 (-kg/m’)

Vapor density lb/R’ (-kg/m’)

Maximum allowable vapor velocity (superficial) ~ft/s (- m/s)

Maximum vapor flow rate ft’/s (- m’/s)

Recommended inside diameter

Hole size and arrangement

Tray thickness

Utilities:

Controls:

Imul8tion:

Tderances:

Comments and draw@:

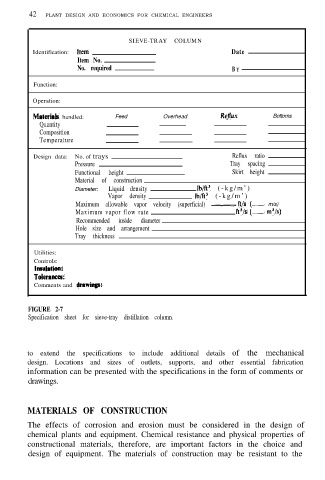

FIGURE 2-7

Specification sheet for sieve-tray distillation column.

to extend the specifications to include additional details of the mechanical

design. Locations and sizes of outlets, supports, and other essential fabrication

information can be presented with the specifications in the form of comments or

drawings.

MATERIALS OF CONSTRUCTION

The effects of corrosion and erosion must be considered in the design of

chemical plants and equipment. Chemical resistance and physical properties of

constructional materials, therefore, are important factors in the choice and

design of equipment. The materials of construction may be resistant to the