Page 217 - Plastics Engineering

P. 217

200 Mechanical Behaviour of Composites

x

6.18 10-~ -3.87 x 104 9.37 x 104

-3.87 x 1.18 x 2.66 x 1 (N mm)-’

-9.37 x 10-5 2.66 x 10-5 2.14 x 10-4

1

-a12

E, = - 1 G,, 1 v,, = -,

E, = - = -

all x h’ a22 x h’ wxh’ a1 1

-a12

vp = -

a22

E, = 24.26 GN/m2, E, = 12.7 GN/m2

Gxy = 6.98 GN/m2, vxy = 0.627, up = 0.328

These values agree with those calculated above. Also, for the applied force

N, = 50 x 2 = 100 N/mm.

[;?I

[5] (=a[;] -”)

=a.

E, = 2.061 x cy = -1.291 x yxy = -3.124 x

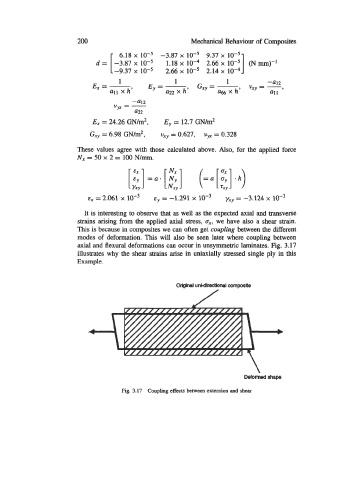

It is interesting to observe that as well as the expected axial and transverse

strains arising from the applied axial stress, a,, we have also a shear strain.

This is because in composites we can often get coupling between the different

modes of deformation. This will also be seen later where coupling between

axial and flexural deformations can occur in unsymmetric laminates. Fig. 3.17

illustrates why the shear strains arise in uniaxially stressed single ply in this

Example.

Orlginal unidirectional composite

Deformed shape

Fig. 3.17 Coupling effects between extension and shear