Page 28 - Plastics Engineering

P. 28

General Properties of Plastics 11

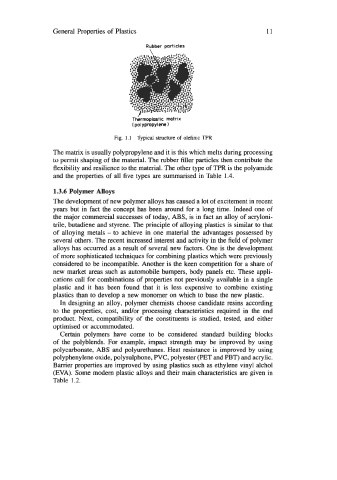

Rubber particles

Tkrmoplastic matrix

I polypmpylenc~

Fig. 1.1 npical structure of olefinic TF'R

The matrix is usually polypropylene and it is this which melts during processing

to permit shaping of the material. The rubber filler particles then contribute the

flexibility and resilience to the material. The other type of TPR is the polyamide

and the properties of all five types are summarised in Table 1.4.

1.3.6 Polymer Alloys

The development of new polymer alloys has caused a lot of excitement in recent

years but in fact the concept has been around for a long time. Indeed one of

the major commercial successes of today, ABS, is in fact an alloy of acryloni-

trile, butadiene and styrene. The principle of alloying plastics is similar to that

of alloying metals - to achieve in one material the advantages possessed by

several others. The recent increased interest and activity in the field of polymer

alloys has occurred as a result of several new factors. One is the development

of more sophisticated techniques for combining plastics which were previously

considered to be incompatible. Another is the keen competition for a share of

new market areas such as automobile bumpers, body panels etc. These appli-

cations call for combinations of properties not previously available in a single

plastic and it has been found that it is less expensive to combine existing

plastics than to develop a new monomer on which to base the new plastic.

In designing an alloy, polymer chemists choose candidate resins according

to the properties, cost, and/or processing characteristics required in the end

product. Next, compatibility of the constituents is studied, tested, and either

optimised or accommodated.

Certain polymers have come to be considered standard building blocks

of the polyblends. For example, impact strength may be improved by using

polycarbonate, ABS and polyurethanes. Heat resistance is improved by using

polyphenylene oxide, polysulphone, PVC, polyester (PET and PBT) and acrylic.

Barrier properties are improved by using plastics such as ethylene vinyl alchol

(EVA). Some modern plastic alloys and their main characteristics are given in

Table 1.2.