Page 29 - Plastics Engineering

P. 29

12 General Properties of Plastics

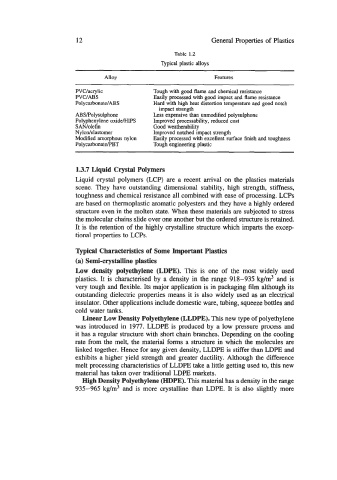

Table 1.2

vpical plastic alloys

Alloy Features

PVClacrylic Tough with good flame and chemical resistance

PVC/ABS Easily processed with good impact and flame resistance

Pol ycarbonate/ABS Hard with high heat distortion temperature and good notch

impact strength

ABSPolysulphone Less expensive than unmodified polysulphone

Polyphenylene oxide/HIPS Improved processability, reduced cost

S AN/olefin Good weatherability

Nylon/elastomer Improved notched impact strength

Modified amorphous nylon Easily processed with excellent surface finish and toughness

PolycarbonatePBT Tough engineering plastic

1.3.7 Liquid Crystal Polymers

Liquid crystal polymers (LCP) are a recent arrival on the plastics materials

scene. They have outstanding dimensional stability, high strength, stiffness,

toughness and chemical resistance all combined with ease of processing. LCPs

are based on thermoplastic aromatic polyesters and they have a highly ordered

structure even in the molten state. When these materials are subjected to stress

the molecular chains slide over one another but the ordered structure is retained.

It is the retention of the highly crystalline structure which imparts the excep-

tional properties to LCPs.

Typical Characteristics of Some Important Plastics

(a) Semi-crystalline plastics

Low density polyethylene (LDPE). This is one of the most widely used

plastics. It is characterised by a density in the range 918-935 kg/m3 and is

very tough and flexible. Its major application is in packaging film although its

outstanding dielectric properties means it is also widely used as an electrical

insulator. Other applications include domestic ware, tubing, squeeze bottles and

cold water tanks.

Linear Low Density Polyethylene (LLDPE). This new type of polyethylene

was introduced in 1977. LLDPE is produced by a low pressure process and

it has a regular structure with short chain branches. Depending on the cooling

rate from the melt, the material forms a structure in which the molecules are

linked together. Hence for any given density, LLDPE is stiffer than LDPE and

exhibits a higher yield strength and greater ductility. Although the difference

melt processing characteristics of LLDPE take a little getting used to, this new

material has taken over traditional LDPE markets.

High Density Polyethylene (HDPE). This material has a density in the range

935-965 kg/m3 and is more crystalline than LDPE. It is also slightly more