Page 31 - Plastics Engineering

P. 31

14 General Properties of Plastics

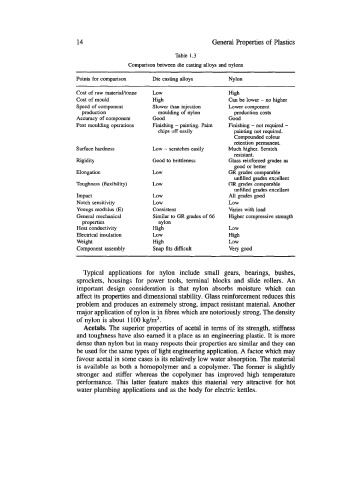

Table 1.3

Comparison between die casting alloys and nylons

Points for comparison Die casting alloys Nylon

Cost of raw materidtonne LOW High

Cost of mould High Can be lower - no higher

Speed of component Slower than injection Lower component

production moulding of nylon production costs

Accuracy of component Good Good

Post moulding operations Finishing - painting. Paint Finishing - not required -

chips off easily painting not required.

Compounded colour

retention permanent.

Surface hardness Low - scratches easily Much higher. Scratch

resistant.

Rigidity Good to brittleness Glass reinforced grades as

good or better

Elongation LOW GR grades comparable

unfilled grades excellent

Toughness (flexibility) LOW GR grades comparable

unfilled grades excellent

Impact Low All grades good

Notch sensitivity LOW LOW

Youngs modulus (E) Consistent Varies with load

General mechanical Similar to GR grades of 66 Higher compressive strength

properties nylon

Heat conductivity High Low

Electrical insulation Low High

Weight High Low

Component assembly Snap fits difficult very good

Typical applications for nylon include small gears, bearings, bushes,

sprockets, housings for power tools, terminal blocks and slide rollers. An

important design consideration is that nylon absorbs moisture which can

affect its properties and dimensional stability. Glass reinforcement reduces this

problem and produces an extremely strong, impact resistant material. Another

major application of nylon is in fibres which are notoriously strong. The density

of nylon is about 1100 kg/m3.

Acetals. The superior properties of acetal in terms of its strength, stiffness

and toughness have also earned it a place as an engineering plastic. It is more

dense than nylon but in many respects their properties are similar and they can

be used for the same types of light engineering application. A factor which may

favour acetal in some cases is its relatively low water absorption. The material

is available as both a homopolymer and a copolymer. The former is slightly

stronger and stiffer whereas the copolymer has improved high temperature

performance. This latter feature makes this material very attractive for hot

water plumbing applications and as the body for electric kettles.