Page 110 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 110

86 Polymer-based Nanocomposites for Energy and Environmental Applications

Fibre cement 6 mm

Fibre cement 6 mm

VIP 17 mm

VIP 17 mm

PCM panel 25 mm

Plywood 5 mm Plywood 5 mm

(A) (B)

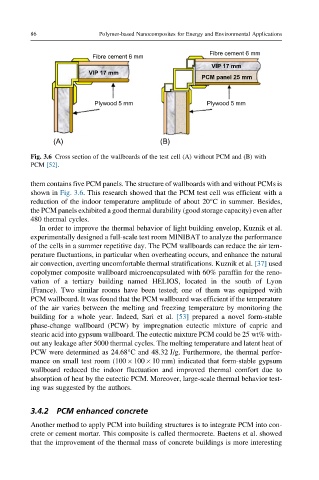

Fig. 3.6 Cross section of the wallboards of the test cell (A) without PCM and (B) with

PCM [52].

them contains five PCM panels. The structure of wallboards with and without PCMs is

shown in Fig. 3.6. This research showed that the PCM test cell was efficient with a

reduction of the indoor temperature amplitude of about 20°C in summer. Besides,

the PCM panels exhibited a good thermal durability (good storage capacity) even after

480 thermal cycles.

In order to improve the thermal behavior of light building envelop, Kuznik et al.

experimentally designed a full-scale test room MINIBAT to analyze the performance

of the cells in a summer repetitive day. The PCM wallboards can reduce the air tem-

perature fluctuations, in particular when overheating occurs, and enhance the natural

air convection, averting uncomfortable thermal stratifications. Kuznik et al. [37] used

copolymer composite wallboard microencapsulated with 60% paraffin for the reno-

vation of a tertiary building named HELIOS, located in the south of Lyon

(France). Two similar rooms have been tested; one of them was equipped with

PCM wallboard. It was found that the PCM wallboard was efficient if the temperature

of the air varies between the melting and freezing temperature by monitoring the

building for a whole year. Indeed, Sari et al. [53] prepared a novel form-stable

phase-change wallboard (PCW) by impregnation eutectic mixture of capric and

stearic acid into gypsum wallboard. The eutectic mixture PCM could be 25 wt% with-

out any leakage after 5000 thermal cycles. The melting temperature and latent heat of

PCW were determined as 24.68°C and 48.32 J/g. Furthermore, the thermal perfor-

mance on small test room (100 100 10 mm) indicated that form-stable gypsum

wallboard reduced the indoor fluctuation and improved thermal comfort due to

absorption of heat by the eutectic PCM. Moreover, large-scale thermal behavior test-

ing was suggested by the authors.

3.4.2 PCM enhanced concrete

Another method to apply PCM into building structures is to integrate PCM into con-

crete or cement mortar. This composite is called thermocrete. Baetens et al. showed

that the improvement of the thermal mass of concrete buildings is more interesting