Page 193 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 193

and of Huang

ATRP by Encapsulation LY, radical

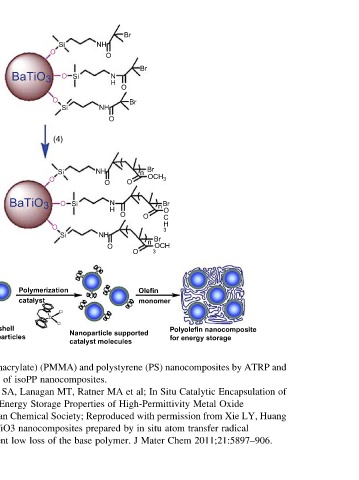

Polyolefin nanocomposite for energy storage nanocomposites Catalytic Oxide Metal Xie from transfer 2011;21:5897–906.

OCH 3 Br n O C H 3 Br OCH monomer (PS) Situ High-Permittivity permission atom situ Chem

Br n 3 Olefin In Mater

Br n O al; with in

Br O J

Br O et by

O O polystyrene

N H O N H MA polymer.

O O O Nanoparticle supported of Reproduced

NH NH NH NH catalyst molecules Ratner prepared

Si Si and nanocomposites. Properties base

Si O Si (4) Si O Si Cl Cl (PMMA) MT, Society; the

O O O O Polymerization Zr Storage nanocomposites of

BaTiO 3 BaTiO 3 catalyst isoPP Lanagan Chemical loss low

Core-shell nanoparticles methacrylate) of SA, Energy and inherent

(2) (3) routes DiBenedetto American

m methacrylate)/BaTiO3 the

OH poly(methyl synthesis Dielectric 2010

OH OH P, with

OH BaTiO 3 OH Br exposure to air (O 2 and moisture) high-k the of Tewari Thickness: Copyright materials

HO HO (1) H 2 O 2 , 105 C, 4h O (4) CuBr/PMDETA, MMA for LA, poly(methyl

HO (2) APS, toluene Br Repeat up to five times routes Illustrations Fredin Shell 5154–64. constant

(1) (3) synthesis (B) Z, Li Variable 22: structured dielectric Chemistry.

BaTiO 3 the respectively. from Having 2010; high of

(A) MAO of permission Mater. Core-shell to Society

OH OH Chem. PK. route

OH Illustration Nanoparticles Royal

OH a

OH HO

OH

OH OH OH OH Agglomerated ferroelectric nanoparticles polymerization, with Jiang 2011

HO (A) C,

HO HO HO (B) Nanocomposites.

5.10 Reproduced Core-Shell Wu Copyright

HO polymerization:

Fig. RAFT XY,