Page 414 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 414

Polymer nanocomposites for dye-sensitized solar cells 371

Heating, 500°C

Ceramic tile Doctor-blade Overturn

Spraying

ITO-PEN Heating, 125°C

(A) Friction-transfer

Compression

(B)

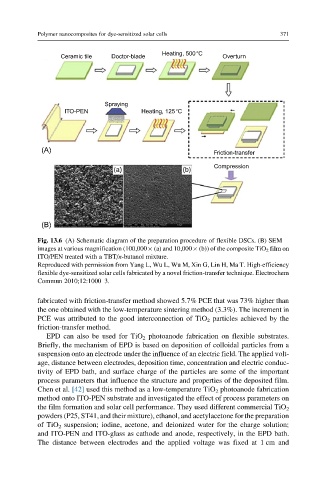

Fig. 13.6 (A) Schematic diagram of the preparation procedure of flexible DSCs. (B) SEM

images at various magnification (100,000 (a) and 10,000 (b)) of the composite TiO 2 film on

ITO/PEN treated with a TBT/n-butanol mixture.

Reproduced with permission from Yang L, Wu L, Wu M, Xin G, Lin H, Ma T. High-efficiency

flexible dye-sensitized solar cells fabricated by a novel friction-transfer technique. Electrochem

Commun 2010;12:1000–3.

fabricated with friction-transfer method showed 5.7% PCE that was 73% higher than

the one obtained with the low-temperature sintering method (3.3%). The increment in

PCE was attributed to the good interconnection of TiO 2 particles achieved by the

friction-transfer method.

EPD can also be used for TiO 2 photoanode fabrication on flexible substrates.

Briefly, the mechanism of EPD is based on deposition of colloidal particles from a

suspension onto an electrode under the influence of an electric field. The applied volt-

age, distance between electrodes, deposition time, concentration and electric conduc-

tivity of EPD bath, and surface charge of the particles are some of the important

process parameters that influence the structure and properties of the deposited film.

Chen et al. [42] used this method as a low-temperature TiO 2 photoanode fabrication

method onto ITO-PEN substrate and investigated the effect of process parameters on

the film formation and solar cell performance. They used different commercial TiO 2

powders (P25, ST41, and their mixture), ethanol, and acetylacetone for the preparation

of TiO 2 suspension; iodine, acetone, and deionized water for the charge solution;

and ITO-PEN and ITO-glass as cathode and anode, respectively, in the EPD bath.

The distance between electrodes and the applied voltage was fixed at 1 cm and