Page 417 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 417

374 Polymer-based Nanocomposites for Energy and Environmental Applications

14

1.0 Sputter Pt/FTO Ox:3l →l +2e – 12

–

–

ECD 50C

Current density (mAcm –2 ) 0.5 ECD 200C J sc (mAcm –2 ) 10 8 6

3

ECD 100C

ECD 150C

0.0

ECD 50C

–0.5 4 2 Sputter Pt/FTO

ECD 100C

ECD 150C

–

–

Red:l 3 +2e →3l – ECD 200C

0

–0.4 –0.2 0.0 0.2 0.4 0.6 0.0 0.2 0.4 0.6

(A) Potential (V) vs SCE (B) V (V)

oc

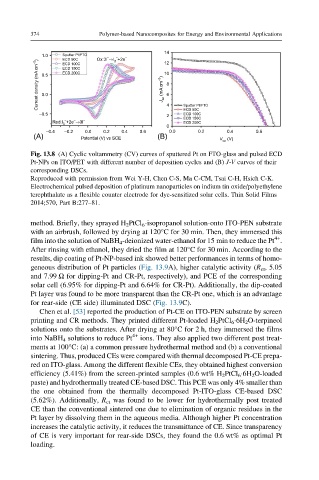

Fig. 13.8 (A) Cyclic voltammetry (CV) curves of sputtered Pt on FTO-glass and pulsed ECD

Pt-NPs on ITO/PET with different number of deposition cycles and (B) J-V curves of their

corresponding DSCs.

Reproduced with permission from Wei Y-H, Chen C-S, Ma C-CM, Tsai C-H, Hsieh C-K.

Electrochemical pulsed deposition of platinum nanoparticles on indium tin oxide/polyethylene

terephthalate as a flexible counter electrode for dye-sensitized solar cells. Thin Solid Films

2014;570, Part B:277–81.

method. Briefly, they sprayed H 2 PtCl 6 -isopropanol solution-onto ITO-PEN substrate

with an airbrush, followed by drying at 120°C for 30 min. Then, they immersed this

4+

film into the solution of NaBH 4 -deionized water-ethanol for 15 min to reduce the Pt .

After rinsing with ethanol, they dried the film at 120°C for 30 min. According to the

results, dip coating of Pt-NP-based ink showed better performances in terms of homo-

geneous distribution of Pt particles (Fig. 13.9A), higher catalytic activity (R ct , 5.05

and 7.99 Ω for dipping-Pt and CR-Pt, respectively), and PCE of the corresponding

solar cell (6.95% for dipping-Pt and 6.64% for CR-Pt). Additionally, the dip-coated

Pt layer was found to be more transparent than the CR-Pt one, which is an advantage

for rear-side (CE side) illuminated DSC (Fig. 13.9C).

Chen et al. [53] reported the production of Pt-CE on ITO-PEN substrate by screen

printing and CR methods. They printed different Pt-loaded H 2 PtCl 6 6H 2 O-terpineol

solutions onto the substrates. After drying at 80°C for 2 h, they immersed the films

into NaBH 4 solutions to reduce Pt 4+ ions. They also applied two different post treat-

ments at 100°C: (a) a common pressure hydrothermal method and (b) a conventional

sintering. Thus, produced CEs were compared with thermal decomposed Pt-CE prepa-

red on ITO-glass. Among the different flexible CEs, they obtained highest conversion

efficiency (5.41%) from the screen-printed samples (0.6 wt% H 2 PtCl 6 6H 2 O-loaded

paste) and hydrothermally treated CE-based DSC. This PCE was only 4% smaller than

the one obtained from the thermally decomposed Pt-ITO-glass CE-based DSC

(5.62%). Additionally, R ct was found to be lower for hydrothermally post treated

CE than the conventional sintered one due to elimination of organic residues in the

Pt layer by dissolving them in the aqueous media. Although higher Pt concentration

increases the catalytic activity, it reduces the transmittance of CE. Since transparency

of CE is very important for rear-side DSCs, they found the 0.6 wt% as optimal Pt

loading.