Page 467 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 467

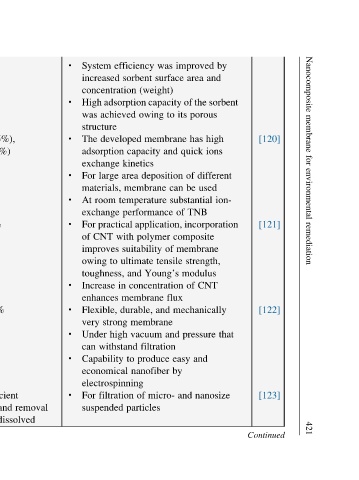

Nanocomposite membrane for environmental remediation 421

[120] [121] [122] [123] Continued

by and high ions different ion- incorporation that nanosize

improved area porous its has quick of used be substantial TNB of composite membrane strength, modulus CNT of mechanically pressure and easy and

was surface (weight) High adsorption capacity of the sorbent to owing membrane and deposition can application, polymer of tensile Young’s concentration flux and membrane and filtration produce by nanofiber micro-

efficiency sorbent achieved developed capacity kinetics area membrane temperature performance with suitability ultimate and in membrane durable, vacuum high withstand to of filtration particles

System increased concentration was structure The adsorption exchange large For materials, room At exchange practical For CNT of improves to owing toughness, Increase enhances Flexible, strong very Under can Capability economical electrospinning For suspended

l l l l l l l l l l l

removal dissolved

(97.5%), (57.7%) 95% 95% efficient and entire

Sr 2+ Cs + Over to Up More turbidity of

and water and

and ions suspended

oil Cs + metal

of Oil-contaminated of oxide of

Removal radioactive Sr 2+ treatment Removal metal nanoparticles Removal particles

nanotube using membrane

nanobelt (Na-TNB) carbon polymer layer electrospun

titanate membrane alcohol) nanofiber membrane

Sodium membrane Incorporated (CNT)-based composite poly(vinyl Carbon Hydrophilic nanofiber