Page 80 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 80

56 Polymer-based Nanocomposites for Energy and Environmental Applications

360

340 4.9° ~ 18.77

320

300

7.8° ~ 11.8 A°

280

260

240

Relative intensity 200

220

180

160

140

120

100

80 Cloisite Na+

60 2% Nanoclay

40

4% Nanoclay

20

0 2 4 6 8 10 12 14 16

2 theta (Degrees)

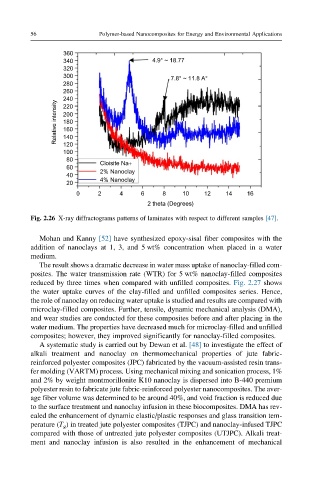

Fig. 2.26 X-ray diffractograms patterns of laminates with respect to different samples [47].

Mohan and Kanny [52] have synthesized epoxy-sisal fiber composites with the

addition of nanoclays at 1, 3, and 5 wt% concentration when placed in a water

medium.

The result shows a dramatic decrease in water mass uptake of nanoclay-filled com-

posites. The water transmission rate (WTR) for 5 wt% nanoclay-filled composites

reduced by three times when compared with unfilled composites. Fig. 2.27 shows

the water uptake curves of the clay-filled and unfilled composites series. Hence,

the role of nanoclay on reducing water uptake is studied and results are compared with

microclay-filled composites. Further, tensile, dynamic mechanical analysis (DMA),

and wear studies are conducted for these composites before and after placing in the

water medium. The properties have decreased much for microclay-filled and unfilled

composites; however, they improved significantly for nanoclay-filled composites.

A systematic study is carried out by Dewan et al. [48] to investigate the effect of

alkali treatment and nanoclay on thermomechanical properties of jute fabric-

reinforced polyester composites (JPC) fabricated by the vacuum-assisted resin trans-

fer molding (VARTM) process. Using mechanical mixing and sonication process, 1%

and 2% by weight montmorillonite K10 nanoclay is dispersed into B-440 premium

polyester resin to fabricate jute fabric-reinforced polyester nanocomposites. The aver-

age fiber volume was determined to be around 40%, and void fraction is reduced due

to the surface treatment and nanoclay infusion in these biocomposites. DMA has rev-

ealed the enhancement of dynamic elastic/plastic responses and glass transition tem-

perature (T g ) in treated jute polyester composites (TJPC) and nanoclay-infused TJPC

compared with those of untreated jute polyester composites (UTJPC). Alkali treat-

ment and nanoclay infusion is also resulted in the enhancement of mechanical