Page 85 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 85

Preparation and properties of nanopolymer advanced composites: A review 61

28

TJPCC

TJPC

26

RJPCC

Tensile strength (MPa) 22

RJPC

24

20

18

16

0 2 4 6 8 10 12 14 16 18 20

(A) Fiber loadings (wt%)

1.6

TJPCC

TJPC

Tensile modulus (GPa) 0.8

RJPCC

1.2

RJPC

0.4

0 5 10 15 20

(B) Fiber loadings (wt%)

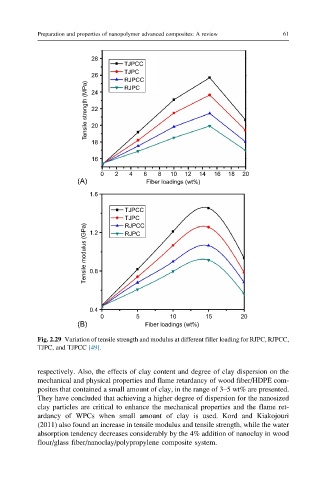

Fig. 2.29 Variation of tensile strength and modulus at different filler loading for RJPC, RJPCC,

TJPC, and TJPCC [49].

respectively. Also, the effects of clay content and degree of clay dispersion on the

mechanical and physical properties and flame retardancy of wood fiber/HDPE com-

posites that contained a small amount of clay, in the range of 3–5 wt% are presented.

They have concluded that achieving a higher degree of dispersion for the nanosized

clay particles are critical to enhance the mechanical properties and the flame ret-

ardancy of WPCs when small amount of clay is used. Kord and Kiakojouri

(2011) also found an increase in tensile modulus and tensile strength, while the water

absorption tendency decreases considerably by the 4% addition of nanoclay in wood

flour/glass fiber/nanoclay/polypropylene composite system.