Page 90 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 90

66 Polymer-based Nanocomposites for Energy and Environmental Applications

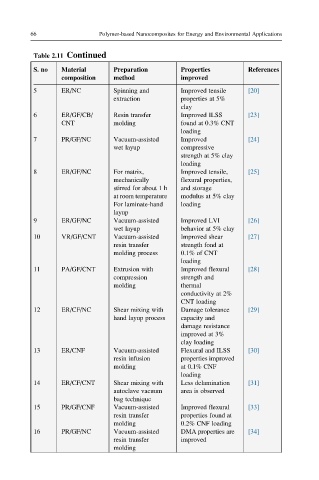

Table 2.11 Continued

S. no Material Preparation Properties References

composition method improved

5 ER/NC Spinning and Improved tensile [20]

extraction properties at 5%

clay

6 ER/GF/CB/ Resin transfer Improved ILSS [23]

CNT molding found at 0.3% CNT

loading

7 PR/GF/NC Vacuum-assisted Improved [24]

wet layup compressive

strength at 5% clay

loading

8 ER/GF/NC For matrix, Improved tensile, [25]

mechanically flexural properties,

stirred for about 1 h and storage

at room temperature modulus at 5% clay

For laminate-hand loading

layup

9 ER/GF/NC Vacuum-assisted Improved LVI [26]

wet layup behavior at 5% clay

10 VR/GF/CNT Vacuum-assisted Improved shear [27]

resin transfer strength fond at

molding process 0.1% of CNT

loading

11 PA/GF/CNT Extrusion with Improved flexural [28]

compression strength and

molding thermal

conductivity at 2%

CNT loading

12 ER/CF/NC Shear mixing with Damage tolerance [29]

hand layup process capacity and

damage resistance

improved at 3%

clay loading

13 ER/CNF Vacuum-assisted Flexural and ILSS [30]

resin infusion properties improved

molding at 0.1% CNF

loading

14 ER/CF/CNT Shear mixing with Less delamination [31]

autoclave vacuum area is observed

bag technique

15 PR/GF/CNF Vacuum-assisted Improved flexural [33]

resin transfer properties found at

molding 0.2% CNF loading

16 PR/GF/NC Vacuum-assisted DMA properties are [34]

resin transfer improved

molding