Page 92 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 92

68 Polymer-based Nanocomposites for Energy and Environmental Applications

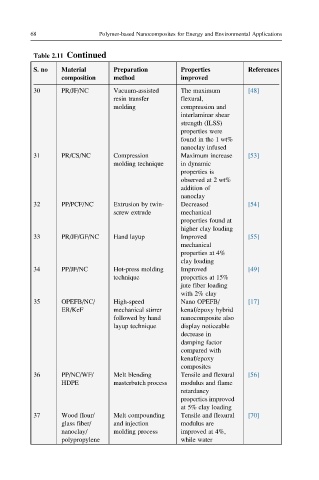

Table 2.11 Continued

S. no Material Preparation Properties References

composition method improved

30 PR/JF/NC Vacuum-assisted The maximum [48]

resin transfer flexural,

molding compression and

interlaminar shear

strength (ILSS)

properties were

found in the 1 wt%

nanoclay infused

31 PR/CS/NC Compression Maximum increase [53]

molding technique in dynamic

properties is

observed at 2 wt%

addition of

nanoclay

32 PP/PCF/NC Extrusion by twin- Decreased [54]

screw extrude mechanical

properties found at

higher clay loading

33 PR/JF/GF/NC Hand layup Improved [55]

mechanical

properties at 4%

clay loading

34 PP/JF/NC Hot-press molding Improved [49]

technique properties at 15%

jute fiber loading

with 2% clay

35 OPEFB/NC/ High-speed Nano OPEFB/ [17]

ER/KeF mechanical stirrer kenaf/epoxy hybrid

followed by hand nanocomposite also

layup technique display noticeable

decrease in

damping factor

compared with

kenaf/epoxy

composites

36 PP/NC/WF/ Melt blending Tensile and flexural [56]

HDPE masterbatch process modulus and flame

retardancy

properties improved

at 5% clay loading

37 Wood flour/ Melt compounding Tensile and flexural [70]

glass fiber/ and injection modulus are

nanoclay/ molding process improved at 4%,

polypropylene while water