Page 89 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 89

Preparation and properties of nanopolymer advanced composites: A review 65

is studied by SEM. The compatibility between new interlayer has been developed by

nanofiller. They found that the tensile strength of PVC sheets containing 10, 20, and

30 wt% of waste laminate (1, 2, and 3 wt% of PP) decreased as PP content increased.

In the samples with lower PP content, mechanical properties has got better as the

filler content increased, while with higher PP content, mechanical properties has

reached its maxima at about 6 wt% of CaCO 3 content.

2.8 Conclusions and summary of research findings

l The current study shows the application of low-content nanofillers can be an efficient tech-

nique for developing of polymers, composites, and blends.

l Currently, nanoclay, CaCO 3 , CNTs, SiO 2 , mica, and graphene are the most valuable

nanofillers displaying great reinforcing effects due to their high thermal stability, improved

mechanical strength, biocompatibility, and great abundance.

l It is concluded that nanoclay minerals and carbon nanotubes are the most promising alter-

native to other nanofillers for improving or modifying the polymer. Thus, the polymer com-

posite properties have exciting potential applications.

l In addition, the development of various preparation techniques and optimization of mixing

process is carried out to its important effect on the final properties.

Hence, this chapter expected to deliver the valuable evidence or literature information

for further research and the elaborative study of nanofiller based on macro-micro

nanopolymeric composites. Moreover, a short summary of some important research

carried out on nanofiller-reinforced polymer composites is presented in Table 2.11.

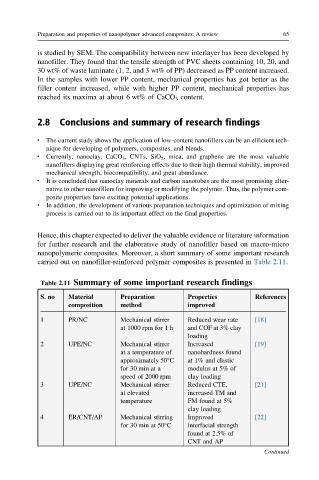

Table 2.11 Summary of some important research findings

S. no Material Preparation Properties References

composition method improved

1 PR/NC Mechanical stirrer Reduced wear rate [18]

at 1000 rpm for 1 h and COF at 3% clay

loading

2 UPE/NC Mechanical stirrer Increased [19]

at a temperature of nanohardness found

approximately 50°C at 1% and elastic

for 30 min at a modulus at 5% of

speed of 2000 rpm clay loading

3 UPE/NC Mechanical stirrer Reduced CTE, [21]

at elevated increased TM and

temperature FM found at 5%

clay loading

4 ER/CNT/AP Mechanical stirring Improved [22]

for 30 min at 50°C interfacial strength

found at 2.5% of

CNT and AP

Continued