Page 91 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 91

Preparation and properties of nanopolymer advanced composites: A review 67

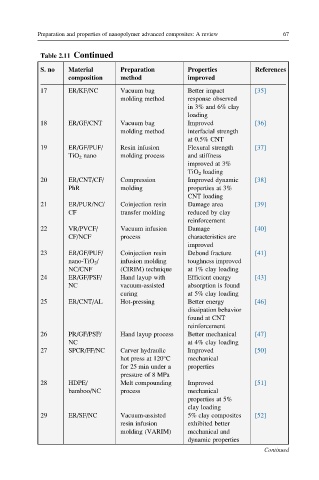

Table 2.11 Continued

S. no Material Preparation Properties References

composition method improved

17 ER/KF/NC Vacuum bag Better impact [35]

molding method response observed

in 3% and 6% clay

loading

18 ER/GF/CNT Vacuum bag Improved [36]

molding method interfacial strength

at 0.5% CNT

19 ER/GF/PUF/ Resin infusion Flexural strength [37]

TiO 2 nano molding process and stiffness

improved at 3%

TiO 2 loading

20 ER/CNT/CF/ Compression Improved dynamic [38]

PhR molding properties at 3%

CNT loading

21 ER/PUR/NC/ Coinjection resin Damage area [39]

CF transfer molding reduced by clay

reinforcement

22 VR/PVCF/ Vacuum infusion Damage [40]

CF/NCF process characteristics are

improved

23 ER/GF/PUF/ Coinjection resin Debond fracture [41]

nano-TiO 2 / infusion molding toughness improved

NC/CNF (CIRIM) technique at 1% clay loading

24 ER/GF/PSF/ Hand layup with Efficient energy [43]

NC vacuum-assisted absorption is found

curing at 5% clay loading

25 ER/CNT/AL Hot-pressing Better energy [46]

dissipation behavior

found at CNT

reinforcement

26 PR/GF/PSF/ Hand layup process Better mechanical [47]

NC at 4% clay loading

27 SPCR/FF/NC Carver hydraulic Improved [50]

hot press at 120°C mechanical

for 25 min under a properties

pressure of 8 MPa

28 HDPE/ Melt compounding Improved [51]

bamboo/NC process mechanical

properties at 5%

clay loading

29 ER/SF/NC Vacuum-assisted 5% clay composites [52]

resin infusion exhibited better

molding (VARIM) mechanical and

dynamic properties

Continued