Page 93 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 93

Preparation and properties of nanopolymer advanced composites: A review 69

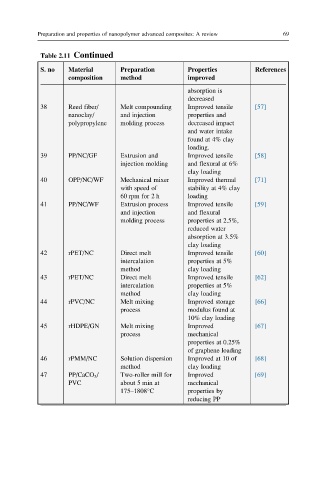

Table 2.11 Continued

S. no Material Preparation Properties References

composition method improved

absorption is

decreased

38 Reed fiber/ Melt compounding Improved tensile [57]

nanoclay/ and injection properties and

polypropylene molding process decreased impact

and water intake

found at 4% clay

loading.

39 PP/NC/GF Extrusion and Improved tensile [58]

injection molding and flexural at 6%

clay loading

40 OPP/NC/WF Mechanical mixer Improved thermal [71]

with speed of stability at 4% clay

60 rpm for 2 h loading

41 PP/NC/WF Extrusion process Improved tensile [59]

and injection and flexural

molding process properties at 2.5%,

reduced water

absorption at 3.5%

clay loading

42 rPET/NC Direct melt Improved tensile [60]

intercalation properties at 5%

method clay loading

43 rPET/NC Direct melt Improved tensile [62]

intercalation properties at 5%

method clay loading

44 rPVC/NC Melt mixing Improved storage [66]

process modulus found at

10% clay loading

45 rHDPE/GN Melt mixing Improved [67]

process mechanical

properties at 0.25%

of graphene loading

46 rPMM/NC Solution dispersion Improved at 10 of [68]

method clay loading

47 PP/CaCO 3 / Two-roller mill for Improved [69]

PVC about 5 min at mechanical

175–1808°C properties by

reducing PP