Page 204 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 204

178 C h a p t e r S e v e n

Steam in jacket

Flow Q

I I

:=0 : + ~: : = L

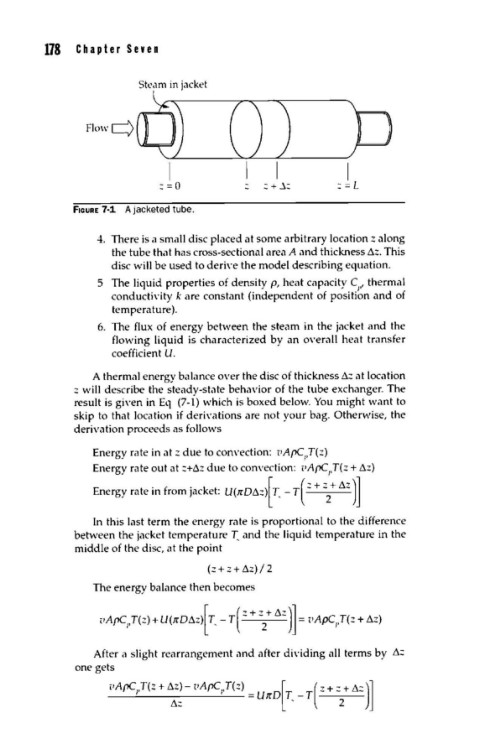

fiGURE 7-1 A jacketed tube.

4. There is a small disc placed at some arbitrary location z along

the tube that has cross-sectional area A and thickness ~z. This

disc will be used to deri,·e the model describing equation.

5 The liquid properties of density p, heat capacity c,,J thermal

conducti,·ity k are constant (independent of position and of

temperature).

6. The flux of energy between the steam in the jacket and the

flowing liquid is characterized by an O\'erall heat transfer

coefficient U.

A thermal energy balance O\'er the disc of thickness~::: at location

::: will describe the steady-state behavior of the tube exchanger. The

result is gi\'en in Eq (7-1) which is boxed below. You might want to

skip to that location if deri\'ations are not your bag. Otherwise, the

derivation proceeds as follows

Energy rate in at z due to convection: 1.'A{>C ,T(z)

1

Energy rate out at:::+~::: due to convection: 1.'Af>C,.T(z + ~z)

t · f

[

· k t

E nergy ra em rom JaC e : U(1rO~:::) T, - T ( ::: + ::: + ~z )]

2

In this last term the energy rate is proportional to the difference

between the jacket temperature T.. and the liquid temperature in the

middle of the disc, at the point

(::: + z + ~z) I 2

The energy balance then becomes

After a slight rearrangement and after di,·iding all terms by ~:::

one gets

<•ArC1,T(z + "':~- PArC1,T(z) = UlrD[T, _ T( z + : + t.: )]

2