Page 205 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 205

Distributed Processes 179

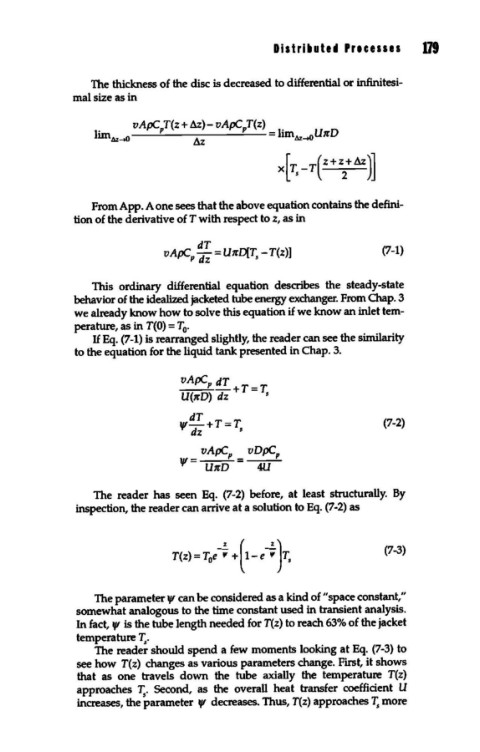

The thickness of the disc is decreased to differential or infinitesi-

mal size as in

From App. A one sees that the above equation contains the defini-

tion of the derivative ofT with respect to z, as in

dT

vApCP Tz = U1rD(T - T(z)] (7-1)

5

This ordinary differential equation describes the steady-state

behavior of the idealized jacketed tube energy exchanger. From Chap. 3

we already know how to solve this equation if we know an inlet tem-

perature, as in T(O) = T •

0

If Eq. (7-1) is rearranged slightly, the reader can see the similarity

to the equation for the liquid tank presented in Chap. 3.

vApCpdT

U(1rD) Tz + T = Ts

dT

ytdz+T=Ts (7-2)

vApCP vDpCP

Yl = U1rD = --ru-

The reader has seen Eq. (7-2) before, at least structurally. By

inspection, the reader can arrive at a solution to Eq. (7-2) as

(7-3)

The parameter yt can be considered as a kind of Space constant,"

11

somewhat analogous to the time constant used in transient analysis.

In fact, yt is the tube length needed for T(z) to reach 63% of the jacket

temperature ~-

The reader should spend a few moments looking at Eq. (7-3) to

see how T(z) changes as various parameters change. First, it shows

that as one travels down the tube axially the temperature T(z)

approaches ~- Second, as the overall heat transfer coefficient U

increases, the parameter yt decreases. Thus, T(z) approaches ~ more