Page 206 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 206

180 Chapter Seven

1

0.95 ......

0.9

0.85 . . .. .. . . '. • • I • •

~ 0.8 .. . . . .

e

Ill 0.75 ..

~

~ 0.7

0.65

0.6

0.55

0.50

0.5 1 1.5 2 2.5 3 3.5 4

Axial distance z

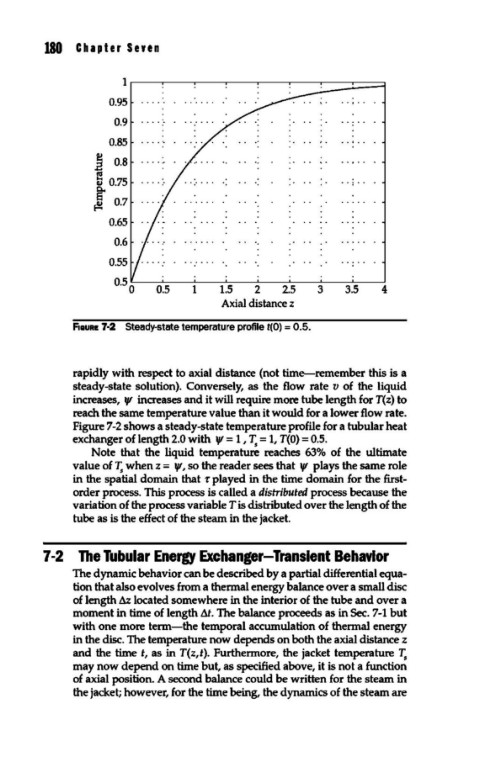

fiGURE 7·2 Steady-state temperature profile t(O) = 0.5.

rapidly with respect to axial distance (not time-remember this is a

steady-state solution). Conversely, as the flow rate v of the liquid

increases, yt increases and it will require more tube length for T(z) to

reach the same temperature value than it would for a lower flow rate.

Figure 7-2 shows a steady-state temperature profile for a tubular heat

exchanger of length 2.0 with yt = 1 , ~ = 1, T(O) = 0.5.

Note that the liquid temperature reaches 63% of the ultimate

value of~ when z = yt, so the reader sees that yt plays the same role

in the spatial domain that 'f played in the time domain for the first-

order process. This process is called a distributed process because the

variation of the process variable Tis distributed over the length of the

tube as is the effect of the steam in the jacket.

7-2 The Tubular Energy Exchanger-Transient Behavior

The dynamic behavior can be described by a partial differential equa-

tion that also evolves from a thermal energy balance over a small disc

of length Az located somewhere in the interior of the tube and over a

moment in time of length At. The balance proceeds as in Sec. 7-1 but

with one more term-the temporal accumulation of thermal energy

in the disc. The temperature now depends on both the axial distance z

and the time t, as in T(z,t). Furthermore, the jacket temperature ~

may now depend on time but, as specified above, it is not a function

of axial position. A second balance could be written for the steam in

the jacket; however, for the time being, the dynamics of the steam are